Nakamura-Tome NT-Flex: Powerful, multitasking CNC lathe

Nakamura-Tome NT-Flex: Compact multitasking CNC lathe delivering power, precision, and flexibility for modern manufacturing needs.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Headland welcomes 8 new team members across Australia, strengthens leadership alignment, and maintains strong customer satisfaction as we focus on agile growth and market support.

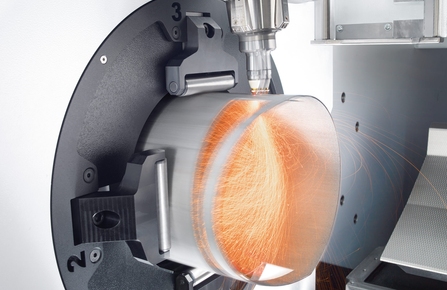

Read how a high-precision manufacturer transforms operations with TRUMPF’s TruLaser Cell 3000 for Laser Metal Deposition (LMD).

Revolutionise your tube cutting with TRUMPF’s next-generation fiber laser systems—delivering up to 366% faster cutting speed and major energy savings.

Read how a bike parts manufacturer streamlines global production with 16 Citizen lathes—and still pushes for more.

Unlock floor space and productivity: Discover how the STOPA LG-E transforms long goods storage for tube and pipe bending manufacturers.

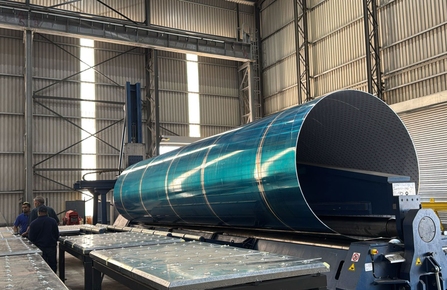

Discover how Faccin 4HEL 12-metre CNC plate roller can streamline operations, enhance quality, and future-proof your manufacturing capabilities.

That’s a wrap! See what made AMW 2025 a standout event for Headland and the future of Australian manufacturing.

Discover how a steel industry leader transformed their material storage with STOPA’s LG-E shelving system—saving space, speeding up retrieval, and cutting downtime by 50%!

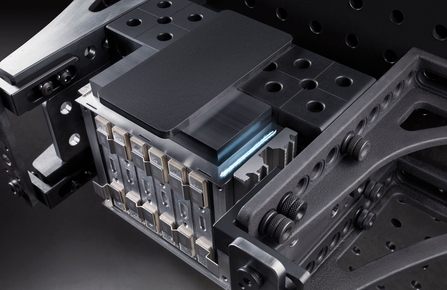

Discover how the TruLaser Station 7000 is transforming energy storage R&D with precision laser welding for next-gen battery and hydrogen cell innovation.

Discover how KraussMaffei is powering Australia and New Zealand’s circular economy with smarter, cleaner injection moulding solutions.

You can also join us for an exclusive TRUMPF INTECH tour — and explore how the latest innovations can drive your business forward.

Discover how a wind tower manufacturing leader revolutionised its production and tripled output with Faccin’s automated plate rolling technology.

In addition to supplying you industry-leading manufacturing equipment, we provide machine servicing, software support and smart manufacturing consulting for all our brands.