Built to last, built to grow: FLUIDRA Australia doubles down on Hanel automation

FLUIDRA expands to four Hanel Lean-Lifts, retrofits existing VLMs, and upgrades picking with Sabl MultiPick, boosting capacity, accuracy, and uptime.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

We pride ourselves on representing world-class brands across almost every manufacturing application. Whether you’re after metal processing equipment, CNC machines, plastics machinery, automated storage or smart factory software – we likely have a solution.

We’re committed to understanding your unique production needs and being a long-term partner to you, whatever stage your production is in. Let’s grow together.

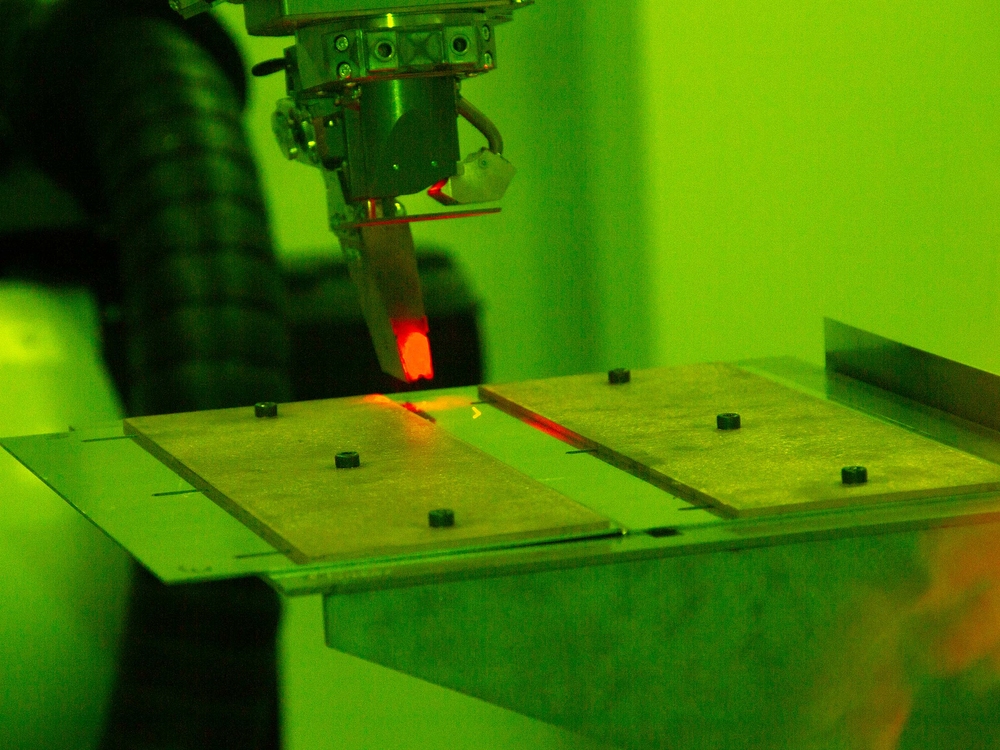

Headland are your one-stop shop for sheet metal processing. We supplying world-class equipment from TRUMPF, JFY, Timesavers, and OMAX.

We are your one-stop shop for large metal processing. With world-class equipment from Faccin, SOCO, Tecoi, Behringer, Roundo & more!

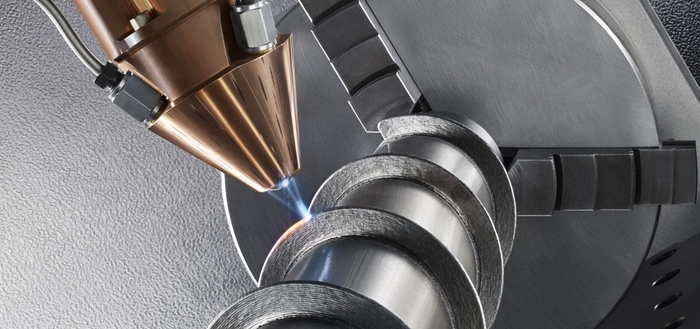

We supply TRUMPF laser technology for manufacturing applications including laser welding, laser marking and 3D laser cutting systems.

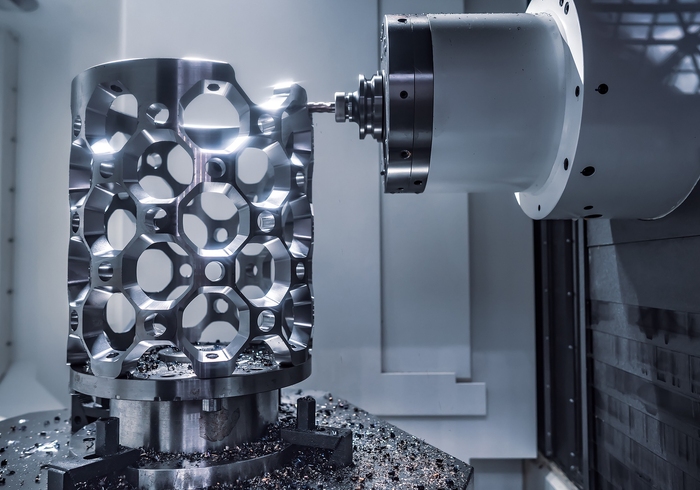

World-class CNC machines for sale in Australia and New Zealand. Vertical and horizontal machining centers, lathes, milling machines, EDM, cylindrical grinding & more.

Automated Warehouse Storage Systems for sale in Australia and New Zealand. Hanel and STOPA storage systems.

Plastic machinery solutions for sale in Australia and New Zealand. Injection Moulding and Extrusion machines from KraussMaffei and Netstal.

TRUMPF power tools for sale in Australia and New Zealand. Electric and battery-powered tools to simplify daily work on construction sites and workshops.

Our machines in stock are available for inspection and immediate delivery. Free shipping is included if you are based in the same state the machine is located.

Discover how U-NEEK Bending transformed their welding processes with advanced automation from TRUMPF.

Discover how MaxiTRANS turned the brink of shutdown into a Smart Factory success—transforming challenges into a competitive edge with the power of smart manufacturing.

Discover how an aerospace manufacturer boosted efficiency and precision with Citizen CNC technology in this case study!

Whether your enquiry is about a machine or service-related, we promise to help you find a solution as quickly as possible.

Please fill in the form and click submit. Once the form is submitted one of our experts will be in touch with you shortly.

In addition to supplying you industry-leading manufacturing equipment, we provide machine servicing, software support and smart manufacturing consulting for all our brands.