Manufacturers are increasingly embracing advanced manufacturing solutions that address a shortage of skilled workers and the demand for production efficiency and quality. As the exclusive seller and service provider for TRUMPF products in Australia and New Zealand, Headland supports flexible automation solutions to help manufacturers leverage the power and precision of TRUMPF laser technology.

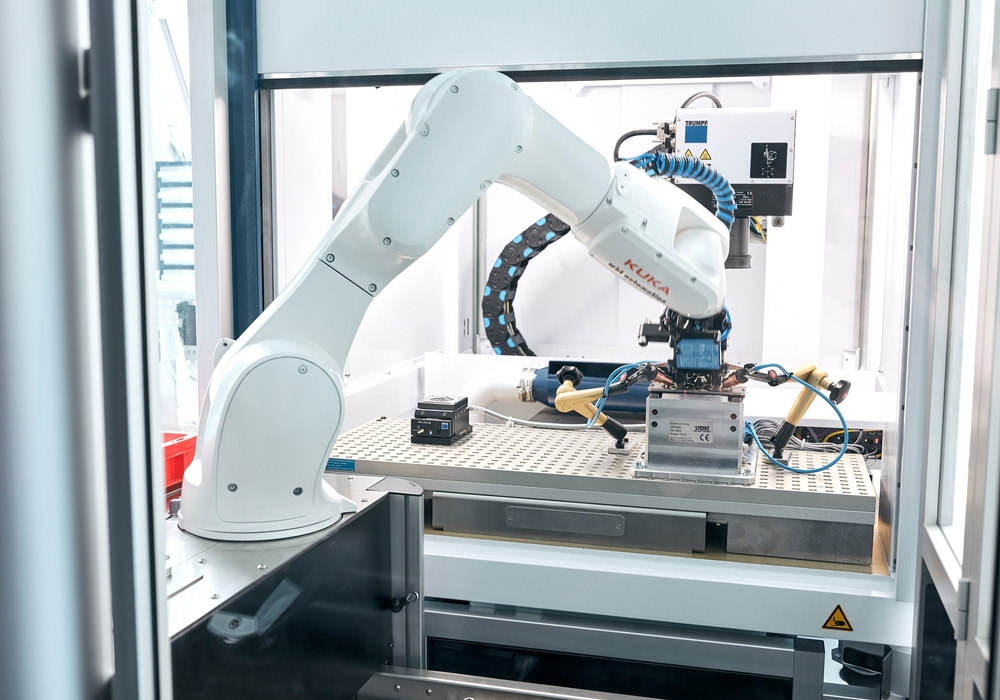

The modular nature of TRUMPF’s automation solutions provides adaptable and expandable options tailored to each manufacturer’s specific needs for volume and variety. A recent example from TRUMPF demonstrated the integration of a ‘dockable’ mobile robotic cell with a TruLaser Station 7000 for laser welding, and a TruMark Station 7000 for laser marking.

Integrating robotic cells and automated workflows with high-performance TRUMPF laser stations enables round-the-clock, error-free production to maximise productivity. In this example production flexibility is maintained by allowing manual operation where it makes sense.

The TruLaser Station 7000, TruMark Station 7000, and mobile robot cell form an automation solution. The robot handles loading and unloading for the welding system and marking laser station. These laser systems weld and mark three-dimensional components such as electronic components, pacemakers, and watch cases.

Increase quality and maintain flexibility with TRUMPF automation solutions

With an automation solution from TRUMPF users can increase the quality of their production, and once the automated production process has been run in, human error is ruled out. The system works without the intervention of a machine operator. The robot independently recognises the correct component and inserts it into the laser station, where a camera checks the component again to confirm the exact position before processing.

This automation solution allows users to set up their production flexibly. If it makes more sense to assemble certain components manually, users can simply undock the robot cell. This is made possible by the electronic and mechanical interfaces on TRUMPF systems, which are specially prepared for robot integration.

These interfaces also provide peace of mind to users who wish to adopt automation in a staged approach, initially running their machines with an operator and adding higher levels of automation in the future according to their needs and budget.

Need to find out how Headland can support your automated laser technology needs?

From medical devices to electronics to precision tools and beyond, TRUMPF automated laser solutions from Headland help leading manufacturers in all industries achieve new levels of quality, efficiency, and reliability. Contact Headland today to discover how flexible TRUMPF automation can benefit your production.