Oakmoore Pty. Ltd., trading as the EGR Group, is a global leader in the design and manufacture of advanced, precision-engineered products. With headquarters in Salisbury, Queensland, EGR serves key sectors across the automotive, building, commercial, and industrial plastics industries.

When Oakmoore needed to relocate a critical piece of TRUMPF TruLaser 3030 equipment, they once again turned to Headland Technology’s PMO team to manage the task with speed, accuracy, and minimal disruption.

The Challenge

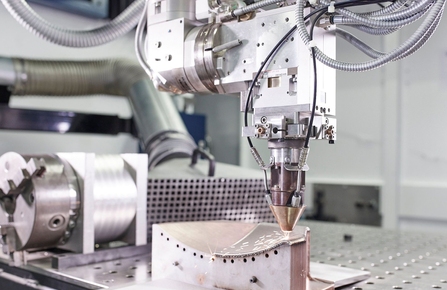

Oakmoore faced a critical equipment relocation under extreme pressure. Their essential TRUMPF TruLaser 3030 needed to be decommissioned, transported and recommissioned within an impossibly tight deadline. The situation became even more urgent as a severe cyclone approached Queensland, threatening to halt all transport operations and leave the team stranded with a partially dismantled system.

About Oakmoore Pty. Ltd. (EGR Group): Oakmoore Pty. Ltd., trading as EGR Group, is a globally recognised designer and manufacturer of precision-engineered solutions, headquartered in Salisbury, Queensland. Established in 1973, EGR Group operates across two strategic divisions: Automotive and building & commercial products. The company is renowned for its vertically integrated manufacturing capabilities, producing a diverse range of products including automotive accessories, high-gloss panels, and extruded plastic sheets. Their vertically integrated operations span product design, extrusion, and manufacturing—delivering innovative solutions to clients in over 180 markets worldwide. More about EGR Group

The solution

Understanding the high stakes, our Project Management Office team (PMO) developed a precise and tightly managed relocation strategy. Led by experienced engineer Jae Hwan Park and supported by the highly skilled PMO team in Victoria, the plan accounted for every detail of the decommissioning, transport, and reinstallation process. Drawing on extensive experience with TRUMPF equipment and laser technology, the team mobilised rapidly and remained in constant communication with Oakmoore throughout the operation. Even with the cyclone impacting local infrastructure and weather conditions, the Headland team adapted in real time, ensuring the relocation progressed without disruption.

The implementation

The process began with careful shutdown and secure packing of the TRUMPF TruLaser 3030. Transportation was coordinated with precision, navigating unpredictable weather conditions and maintaining the timeline despite external pressure. On arrival at the new site, the team immediately commenced recommissioning, conducting calibration and validation to ensure the laser system was fully operational within the deadline. Thanks to proactive planning, streamlined processes, and strong on-site collaboration, the entire move was completed with hours to spare—without compromising safety or quality.

The outcome

In just 55 hours, the relocation was successfully completed—setting a benchmark for speed and operational efficiency. Not only was the project delivered within the critical time frame, but it also came in under budget, earning Oakmoore a cost credit. The client praised the professionalism and technical expertise of the team, with recognition of Jae Hwan Park’s leadership and the PMO team’s attention to detail. The result was a seamless transition with zero production downtime and another milestone in the trusted relationship between Oakmoore and Headland.

Why does it matter?

This project demonstrates our PMO’s capability to execute high-stakes equipment relocations with speed, precision, and resilience—even in adverse weather conditions. The team’s proactive communication, technical depth, and collaborative approach ensured minimal disruption and maximum value for the client. For Oakmoore, the success of this second laser relocation reaffirms that our Project Management Office team is its preferred partner for complex technology moves.

Are you planning to move a critical operational machine?

If your business is preparing for a machinery relocation, installation, commissioning, or decommissioning—whether local or interstate—Our PMO team is ready to support you. Our experienced project management professionals will work with you to create a customised relocation plan that ensures minimal disruption, optimal safety, and complete peace of mind. Contact our Project Management Office team to discuss your project requirements.