To book a viewing contact Nigel Kelly on 0429 417 489 or email him at nigelk@headland.com.au.

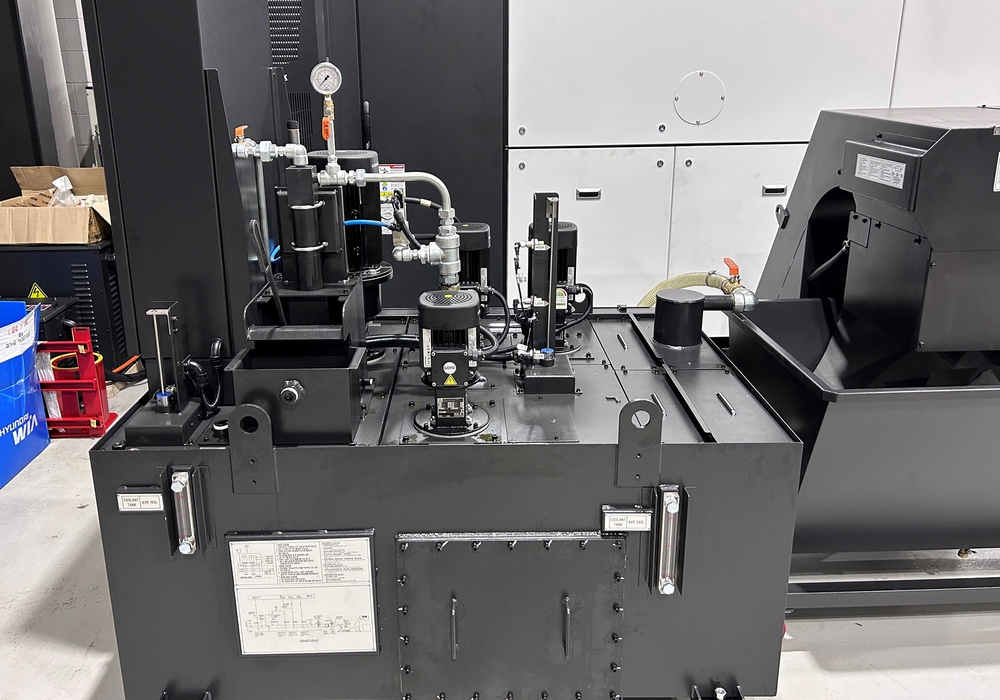

The XF6300 is a highly advanced 5-axis machining center especially suited for manufacturing precision parts. This machine combines the latest advancements in CNC technology to minimise thermal distortion and vibration for maximum repeatability.

Suitable industries

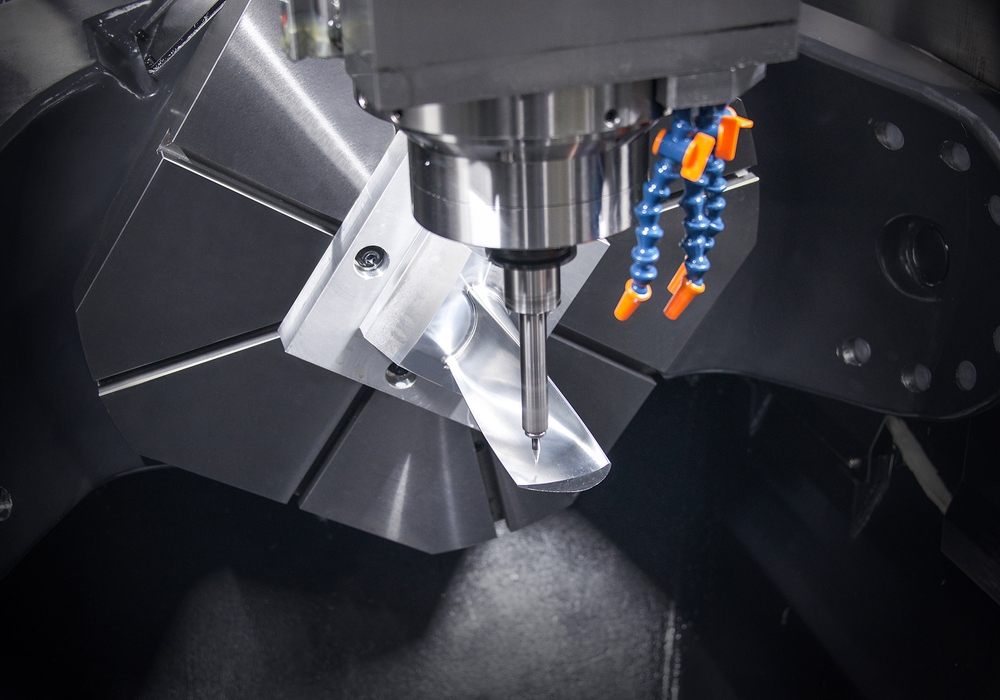

Aerospace: Machining challenging composite and aluminium aerospace components with tight form tolerances is possible thanks to the accuracy and low vibration of XF machines.

Mould Manufacturing: Perfect for mould components with intricate cooling channels and surface finishes. Rigid acceleration/deceleration prevents tool marks and there is no accuracy loss from thermal growth.

Medical: Biocompatible orthopaedic knee/hip implants that require dimensions within microns and no surface defects are achieved due to precision machining.

Key benefits of the machine

- Column/Bed all-in-one structure: XF series are designed with an integrated one-piece column-bed structure that provides superior stability when compared with separate structures.

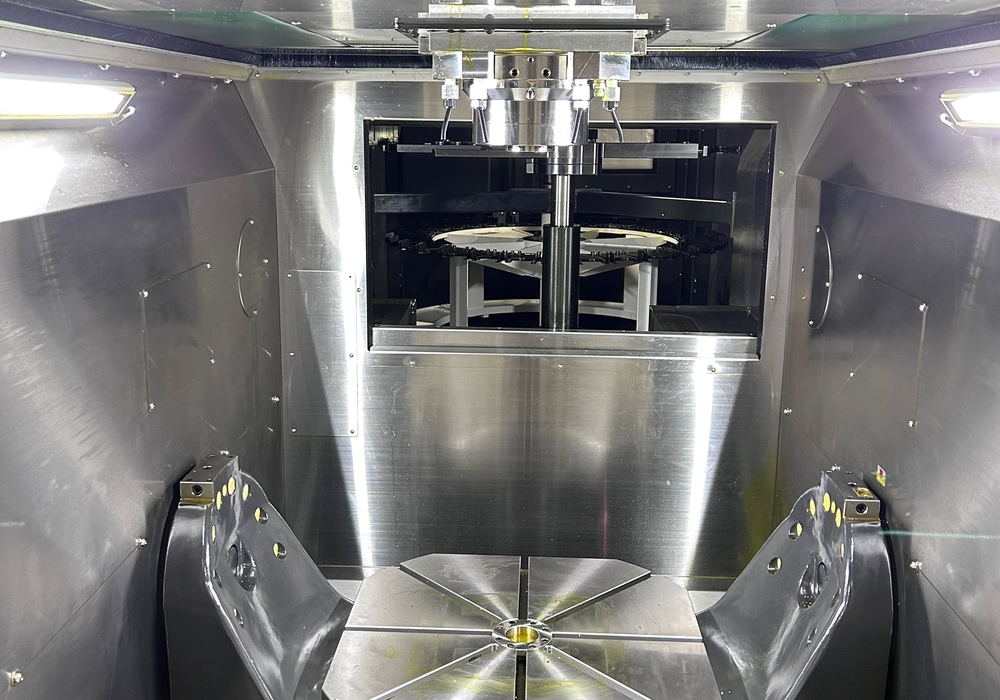

- DDM Tilting Rotary Table: The DDM rotary table is designed to embody highly accurate high-speed simultaneous 5-axis motion which allows for the machining of complex prismatic parts with superior accuracy and surface finishes.

- Box-in-Box Structure (X/Z Axis): The pusher (head body) in the saddle of X-axis, which surrounds the spindle cartridge, is designed with box-inbox type.

- Symmetric Structure of Z-axis: Vibration and thermal displacement during travel can be minimised by the symmetric structure of Z-axis where the travel axis is aligned with the weight centre of spindle.

- Y-axis Double Ball Screw Structure: The Y-axis is driven by two ball screws and feed motors to provide unprecedented speed, accuracy, stability, and acceleration than general-purpose machines.

- Flexible Operation: User-friendly SIEMENS S840D controller coupled with 5-axis capabilities lets you handle 3D contours and intricate geometries with ease.

For a more comprehensive overview, refer to the brochure referenced below the article.

Book your viewing today

To book a viewing contact Nigel Kelly on 0429 417 489 or email him at nigelk@headland.com.au.