Time and space are valuable commodities in the world of metalworking. Recognising this, Timesavers International, the global leader in wide belt grinding machines, has launched a compact solution for deburring and edge rounding that aligns perfectly with the mantra of efficiency. This new offering, part of the 12 RB series, debuted at the prestigious Blechexpo in Stuttgart, Germany,

Since 2009, Timesavers International pioneered the ‘RB‘ designation, signifying the Rotary Brush technique. This technique is adept at edge rounding and creating a smooth radius. Formerly, Timesavers machines featured eight or four rotary brushes, each equipped with over a hundred abrasive flaps. The flexible material of the brush delicately impacts the edges of metal components, grinding corners while gliding smoothly over the surface, leaving the upper side unscathed.

The RB machine range has evolved over the years. The 42 RB series, introduced as the first deburring machine with rotary brush technology, boasts a working width of 1350 mm or 1600 mm, with eight brushes covering the entire surface. This powerhouse effortlessly rounds edges up to a 2 mm radius, handling deburring, laser oxide removal, slag removal, and finishing—a versatile solution for products of all sizes. Subsequently, the 32 RB series emerged in 2017, featuring four rotary brushes and a working width of 1100 mm. In 2020, Timesavers integrated the RB technique into a more compact 600 mm wide machine—the 22 RB series.

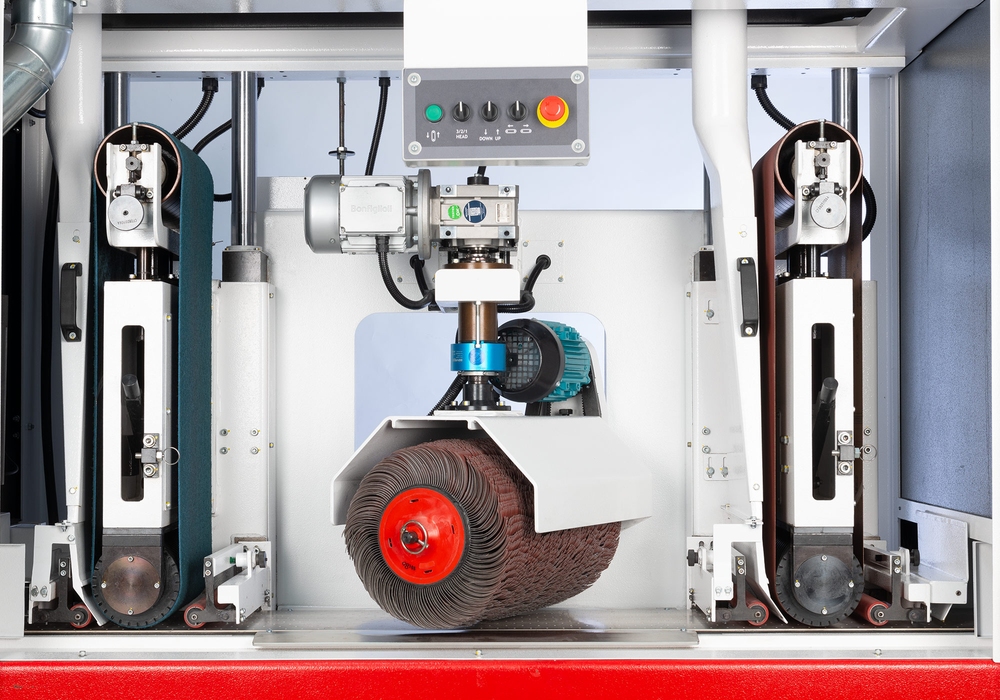

Meet the new space-efficient 12 RB series, featuring the latest edge-rounding and deburring technology

Recognising the need for an even more space-efficient edge-rounding machine, Timesavers developed the 12 RB series. This compact solution replaces manual deburring without consuming excessive space. The machine incorporates the rotary brush technique with a 530 mm long brush and a 350 mm diameter. Despite the challenge, the outcome is impressive—a 300 mm working width with three machine heads configured as WRBW (Wide belt for grinding, rotary brush for edge rounding, and another wide belt for finishing).

Designed with user-friendly features, the 12 RB series includes a large Siemens HMI touchscreen for machine control, frequency-controlled motors, and motorised height adjustment. Noteworthy is its constant pass at a fixed table height of 970 mm, irrespective of product thickness (ranging from 3 mm to 100 mm), streamlining the deburring process.

The 12 RB series accommodates product sizes from 20 x 20 mm up to 300 mm in width. A robust vacuum table ensures secure holding, even for smaller items like coins during grinding.

Ensuring a clean and safe working environment, Timesavers partners exclusively with top-tier companies for dust extraction systems. In Germany, Absaugwerk GmbH specialises in extraction systems, including wet separators that seamlessly complement Timesavers machines.

Perfecting sheet metal fabrication – 12 RB Series handles steel, stainless steel, aluminium, and copper with ease

For optimal results, the 12 RB series offers a wide selection of abrasive materials. Timesavers has partnered with 3M to ensure top-notch quality in abrasive belts, ranging from coarse grits like #60 to fine grits up to #400. The 3M Scotch-Brite belt is a popular choice for finishing various metals. Application experts at Timesavers collaborate with users, offering advice on the right tooling for specific needs. Ideal for sheet metal fabrication, these wide belt grinding machines handle various materials such as steel, stainless steel, aluminium, and copper.

One of the standout features of the 12 RB series is its quick tool change capability. Brushes are available in various grits, flap sizes, and minerals, allowing for versatility based on specific requirements. This flexibility is crucial for companies looking to eliminate laser oxide or plasma cut parts, significantly enhancing the quality and strength of welds.

Are you looking for an efficient, space-saving machine that expertly handles deburring, edge rounding, and finishing to boost productivity and cut costs?

Contact our Timesavers experts today to discover how Headland’s technology solutions can help you enhance efficiency and contribute to cost savings.