In manufacturing, profit margins are constantly under pressure from material waste, human error, and productivity bottlenecks. Yet, for many companies, material flow and storage are considered only after production machinery investments are made, a decision that can create costly inefficiencies. STOPA’s automated storage systems, delivered in partnership with Headland Technology, address these pain points head-on, transforming storage from a passive necessity into a growth-enabling, profit-driving asset.

The risks of not automating material storage

Without an automated material handling system, manufacturers face three recurring challenges that directly impact profitability and growth:

Material damage from multiple handling: Frequent manual movement of materials increases the risk of scratches, dents, or other damage. This leads to costly rework, waste, and unnecessary material replacement, eroding profit margins.

Human error in material picking: Selecting the wrong grade, thickness, or batch of material can cause production delays, wasted processing time, and rework. In high-output environments, these errors compound quickly into significant profit losses.

Labour shortages and productivity bottlenecks: With skilled labour in short supply, relying on manual storage and retrieval creates a growth bottleneck. Without automation, expanding output or introducing new product lines becomes harder, slower, and more expensive.

STOPA: More than just a storage supplier

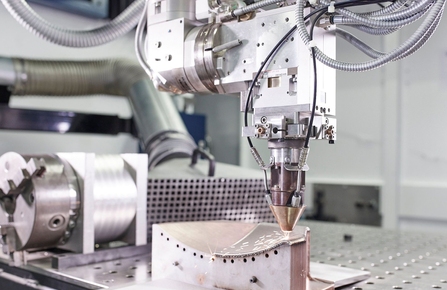

STOPA is not simply a manufacturer of automated storage systems; it is a material flow partner. With over 2,000 systems installed globally, STOPA offers extensive experience in production layout consulting, helping manufacturers design the most efficient workflow from day one.

Key advantages include:

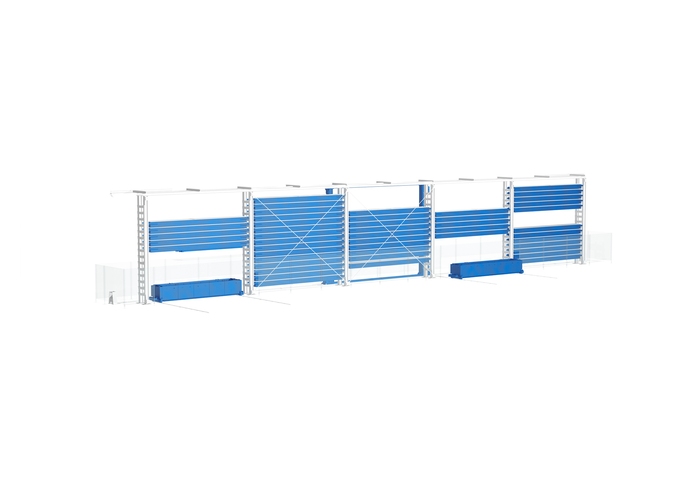

- Scalable systems for any business size: From small workshops to large-scale production facilities, STOPA’s solutions grow with a company’s material flow needs.

- Fully customisable designs: Accommodates tight spaces, oversized materials, and unique plant layouts. Competitors often offer fewer configuration and system size options.

- Proven factory layout expertise: STOPA’s project teams quickly identify optimal layouts that improve flow between storage and machinery, reducing idle time and bottlenecks.

- Smart reporting and traceability: Turn your storage system into a strategic data asset with actionable insights into usage, stock turnover, idle inventory, and machine-material flow.

Risk minimiser and growth enabler

STOPA automated storage addresses each operational risk while enabling scalable growth:

- Risk minimisation: Reduced handling means less damage; automated selection eliminates picking errors; built-in reporting reduces uncertainty and stock discrepancies.

- Growth enablement: Increased throughput without additional labour; optimised layouts free up floor space for expansion; fast, accurate material delivery supports new product lines and increased production schedules.

- Cost reduction = Profit gain: Every reduction in waste, rework, and labour hours directly improves the bottom line.

Why STOPA is a great investment

Most companies prioritise production machinery, leaving material storage as an afterthought, yet material flow is the foundation on which production efficiency is built. Headland and STOPA can consult early in the planning stage to design the most optimised factory layout, ensuring that machinery, people, and materials work together seamlessly.

STOPA’s track record includes complex material flow projects with high-profile clients, integrating seamlessly with production machinery for maximum efficiency. The partnership is supported by:

- A highly capable service engineering team: Ensuring rapid response and ongoing system performance.

- A dedicated project management team: Providing peace of mind for projects with multiple stakeholders and high complexity.

The Headland and STOPA partnership

Headland Technology’s long-standing partnership with STOPA delivers more than just a piece of equipment; it offers a complete material flow solution that integrates storage, production, and long-term factory planning. This combination of global engineering expertise and local project delivery makes STOPA systems a secure investment for manufacturers seeking to minimise risk, enable growth, and protect profits.

STOPA: Storage that works as hard as your production machinery.

Does some of this sound familiar to you?

If so, contact our STOPA and automated storage experts to discuss how we can help you turn your material storage into one of your strongest competitive advantages.