With more than 25 years of experience, Hygrade Laser Profiling has established itself as one of the most trusted names in laser cutting throughout Sydney, NSW. Under the leadership of Director and Owner Michael White, the business consistently delivers precision sheet metal fabrication, robotic welding, and metal bending services to customers across New South Wales.

Michael and his team at Hygrade are determined to provide the very best quality laser cutting, robotic welding and metal bending services to their customers in New South Wales.

Although they don’t manufacture, Michael describes the business as “just a job shop,” where they simply construct specific parts for their customer.

“We don’t specialise in producing just one type of product, we are certainly flexible with what our customers require,” Michael says. “At Hygrade we are determined to produce products that are precise and that are at a high standard if they are not up to scratch, they don’t go out,” he says.

About Hygrade Laser Profiling: Founded in 1989, Hygrade Laser Profiling has been at the forefront of advanced laser cutting services in Sydney for over three decades. As dedicated laser-cutting specialists, they have built their business on combining precision engineering, professional service delivery, and a lasting reputation that underpins every project they undertake.

The company has evolved from its humble beginnings into a comprehensive metal fabrication powerhouse, offering everything from tailored sheet metal fabrication to complete production support. Their commitment to excellence has made them the go-to partner for businesses across New South Wales seeking reliable, high-quality metal fabrication solutions.

What sets Hygrade apart is its unwavering dedication to quality control and customer satisfaction. Their state-of-the-art facility houses cutting-edge equipment operated by skilled technicians who understand that in precision manufacturing, there’s no room for compromise. Whether working on small-scale custom pieces or large industrial projects, Hygrade maintains the same exacting standards that have earned it recognition as leader in the Sydney laser cutting market. More about Hygrade Laser Profiling

Laser cutting for architectural metal design

One of Hygrade’s most impressive showcases was a large-scale architectural metal fabrication project for a prestigious Sydney CBD apartment complex. Collaborating with Architectural Metal Consultancy & Fabrication, Hygrade laser-cut thousands of identical metal leaves for a striking mural installation that would become a defining feature of the building.

“Using our laser cutting techniques, we were able to create each leaf to the exact same standard,” says Michael. “When they were installed, the effect was incredible uniform shapes that move in the wind, creating a real example of architectural brilliance.”

This project exemplified how precision sheet metal cutting can transform ambitious architectural visions into stunning reality. The complexity of producing thousands of identical components while maintaining perfect consistency demonstrated Hygrade’s capability to handle high-volume, precision-critical projects that define Sydney’s modern architectural landscape.

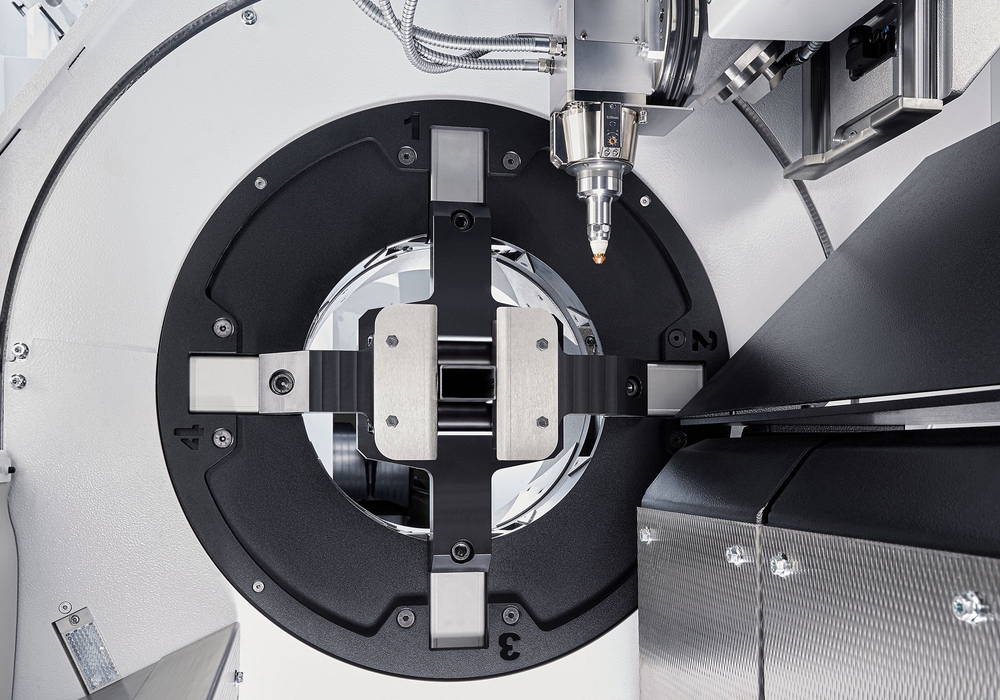

The power of TRUMPF laser technology

To maintain their competitive edge in the rapidly evolving world of metal fabrication, Hygrade has made substantial investments in advanced technology. Michael believes this commitment to technological excellence is absolutely central to the company’s continued success and growth.

The upgrade to modern TRUMPF systems has revolutionised Hygrade’s operations, dramatically improving efficiency, enhancing accuracy, and expanding their capacity to tackle increasingly complex laser cutting jobs throughout Sydney. This technological advancement has positioned them to serve a broader range of industries while maintaining their reputation for exceptional quality.

Strategic partnership with Headland Technology

Hygrade’s strategic partnership with Headland Technology ensures continuous access to the latest TRUMPF machines and expert technical support. This collaborative relationship enables the team to stay at the cutting edge of metal fabrication technology while continuing to offer premium sheet metal fabrication and laser cutting services across diverse industries, from transport and manufacturing to architecture and construction.

The partnership goes beyond equipment supply, providing ongoing training, maintenance support, and access to the latest innovations in laser cutting technology, ensuring Hygrade remains Sydney’s premier destination for precision metal fabrication.

Interested in learning more about how TRUMPF technology can transform your metal fabrication capabilities?

Whether you’re an architect looking to bring complex designs to life, a manufacturer seeking precision components, or an engineer exploring cutting-edge laser cutting solutions, our experts are ready to help.

Connect with our metal fabrication and TRUMPF experts to explore how TRUMPF’s innovative laser technology solutions deliver unmatched accuracy, productivity, and design excellence for your upcoming projects.