The Australian government recently announced that it will consider banning the import and sale of engineered stone benchtops later this year due to health concerns. Engineered stone products often contain high levels of crystalline silica, which when cut dry can create fine silica dust that workers breathe in. Respirable silica puts stonemasons at a high risk for silicosis and lung cancer. While a ban aims to prevent further risk, it raises questions about how to handle existing benchtop manufacturing safely. Using wet-cutting methods eliminates dangerous silica dust. Abrasive water jet cutting machines are an ideal wet-cutting solution for safe engineered stone fabrication and OMAX is the global leader in this technology.

A safer stonemasonry future: Embracing water processing and automation

In the active work of stonemasonry, the strategic integration of water processing and automation is pioneering a new age of safety and efficiency, with specialised machinery such as abrasive waterjets using a high-pressure stream of water mixed with Garnet abrasive to precisely cut materials without generating harmful dust. Any material cut is contained within the catcher tank of the system for safe disposal. With no dangerous airborne silica particles released, water jet technology protects worker health and safety. OMAX water jets can accommodate engineered stone slabs and cut intricate designs while keeping the operators safe.

By adopting abrasive water jet technology for engineered stone fabrication, companies can precisely cut stone designs while providing a clean, safe alternative ensuring the health of employees.

OMAX offers safe and efficient abrasive water jet cutting of granite, marble, and quartz

OMAX, a leading provider of abrasive waterjet cutting solutions, offers to safely cut stone materials such as granite, marble, and engineered quartz. OMAX water jet guidelines aim to enhance the efficiency and precision of the cutting process while minimising the risk of damage to the materials.

When working with stone products, it is crucial to have the technology to process these materials safely and with reliable results. OMAX has special features available as standard, which will automatically work to keep the material from being damaged during the cutting process. Special attention should be given to materials like marble, which may contain soft veins, as these can potentially lead to breakage. To ensure even cuts and prevent cracks, it is advised to support the material uniformly during the cutting process.

When cutting ceramic materials, our waterjet experts can provide specific tips tailored to the characteristics of your materials to ensure the best results are achieved efficiently and consistently. When working with harder ceramics like engineered quartz, it is recommended to use tougher abrasives such as aluminium oxide for optimal results. Additionally, cutting ceramics in their “green” state before firing can provide certain advantages in the fabrication process. By following certain guidelines, operators can optimise their cutting processes and achieve superior results when working with stone and ceramic materials.

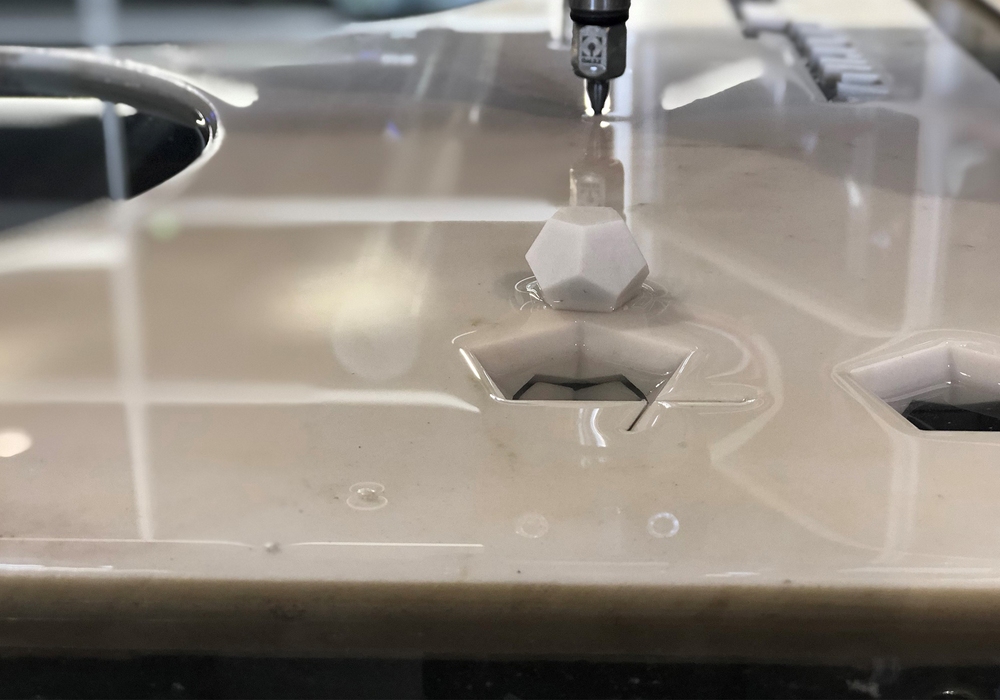

OMAX A-jet 5 axis system delivers accurate mitred cuts on demand

The accuracy of mitre cuts is critical for achieving a polished, professional appearance, ensuring structural stability, and avoiding the costs and inconveniences associated with rework. It is a key element in various applications, including woodworking, construction, and any project where precise angles and joints are essential. The A-jet 5-axis system from OMAX is the most accurate system for applying bevel edges. When this is matched with the easy-to-program software, the OMAX system provides results that are unmatched in the industry.

In summary: The controlled and enclosed nature of industrial water jets like OMAX minimises chances for workplace injuries while cutting and crafting customised kitchen and bathroom countertops and benches from engineered stone. Overall, the OMAX water jet technology delivers excellent safety compared to conventional cutting equipment.

Are looking into additional safety measures to protect your workers during the stone-cutting and finishing process?

Our team of OMAX abrasive water jet experts are dedicated to assisting you in identifying and implementing the optimal solution tailored to meet the specific requirements of your stone production operations.