In industrial manufacturing, precision is paramount. As components shrink in size and grow in complexity, manufacturers need efficient, accurate methods to join materials without compromising structural integrity. Traditional welding techniques often introduce excessive heat leading to warping, material distortion, and weakened connections—especially when working with delicate or dissimilar metals.

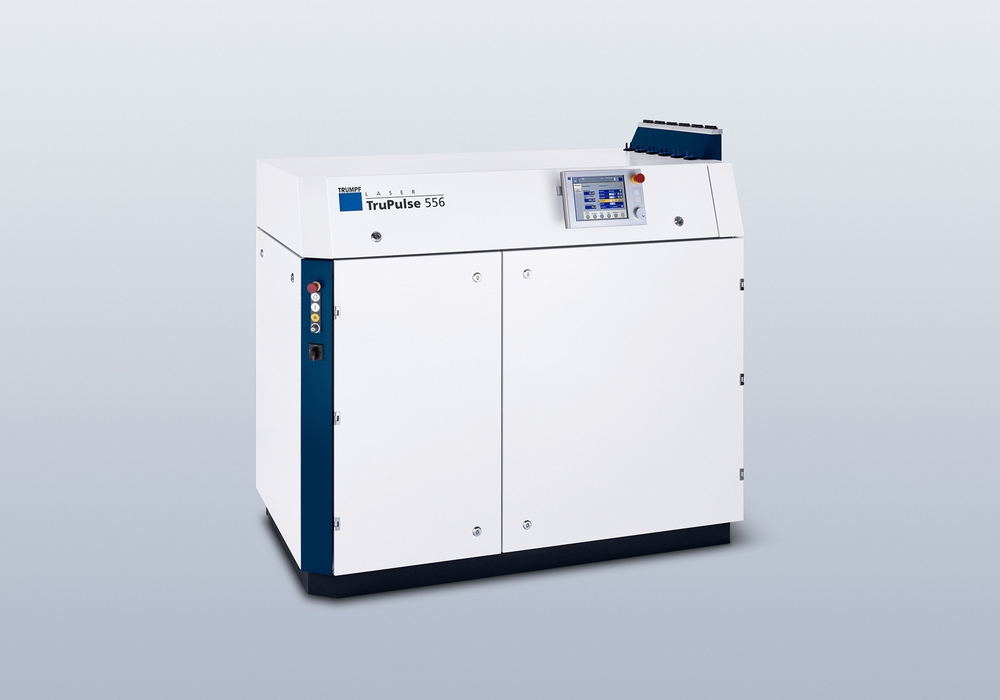

To overcome these challenges, TRUMPF has developed nanosecond welding, an advanced laser micro-welding technique that uses ultra-short laser pulses. This method ensures minimal heat input, maximum precision, and enhanced structural stability, making it ideal for modern manufacturing demands.

Enhancing energy storage efficiency with nanosecond laser welding

With the global rise in demand for renewable energy solutions and efficient energy storage, battery technology has taken centre stage. Precise welding of battery components—such as thin foils, electrodes, and connectors—is critical to improving battery performance and longevity. TRUMPF’s nanosecond laser welding technology delivers strong, reliable connections in energy storage systems.

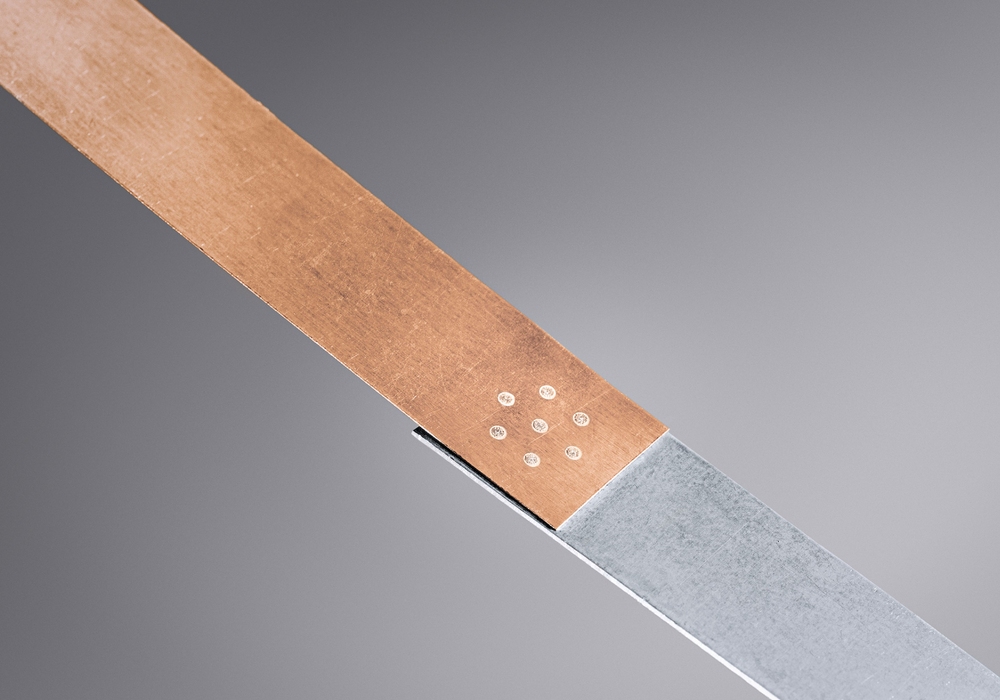

In battery production, joining dissimilar materials like aluminium and copper is essential for optimising electrical conductivity and thermal management. The nanosecond laser micro-welding process minimises the formation of brittle intermetallic compounds, ensuring superior mechanical connections, enhanced electrical performance, and extended battery lifespan. This technology is particularly beneficial for manufacturing lithium-ion and solid-state batteries used in electric vehicles, grid storage, and portable electronics.

Understanding nanosecond welding

TRUMPF’s nanosecond welding technology relies on high-frequency laser pulses, each lasting mere nanosecond (billionths of a second). This creates an extremely localised heat effect, melting only a small volume of material at a time. Unlike traditional welding methods that rely on sustained heating, nanosecond laser micro-welding delivers precise, stable welds without structural deformation.

A key advantage of this method is its ability to weld a wide range of metals, including traditionally challenging dissimilar combinations. This makes it invaluable for industries like electronics, medical devices, and precision engineering.

Key advantages of nanosecond laser welding

- Unmatched precision: Controlled nanosecond pulses enable highly accurate welds, even at microscopic levels, meeting the exact tolerances required in aerospace, microelectronics, and medical device manufacturing.

- Minimal heat input and material distortion: The ultra-short pulses prevent warping, cracking, and material degradation, making it ideal for thin or intricately designed components.

- Versatility in material compatibility: Nanosecond welding can join dissimilar metals like copper and aluminium or titanium and stainless steel, reducing brittle intermetallic compounds and ensuring durable welds.

- Efficiency and repeatability: This method is energy-efficient, reduces material waste, and delivers consistent, repeatable results—critical for mass production and automated manufacturing.

How nanosecond laser welding works

Nanosecond laser welding uses ultra-short laser pulses that penetrate just a few micrometres into the material. Unlike continuous-wave lasers, nanosecond lasers deliver rapid, high-intensity pulses that create a micro keyhole effect. This allows for deep, narrow welds with a high aspect ratio, ensuring strong connections while preserving fine details.

The process melts only a small amount of material at a time, preventing excessive mixing of metals and preserving the unique properties of each material. By adjusting pulse shape and frequency, manufacturers can tailor penetration depth and weld characteristics to meet specific application requirements.

The future of high-precision welding in energy storage

As industries transition to sustainable energy solutions, advanced welding technologies are essential for improving battery efficiency, safety, and longevity. TRUMPF’s nanosecond laser micro welding is set to play a pivotal role in developing next-generation batteries, ensuring robust connections that enhance energy transfer and thermal stability.

For energy sector manufacturers, this technology offers a highly effective way to optimize production processes while maintaining the highest quality standards. Whether in electric vehicles, grid storage, or consumer electronics, nanosecond welding enables the seamless integration of high-performance energy storage solutions.

Conclusion

TRUMPF’s nanosecond laser welding is a game-changing solution for manufacturers seeking precision, efficiency, and material compatibility. By minimising heat effects and enabling the seamless joining of complex materials, this technology is driving the future of high-performance manufacturing. With its ability to deliver consistent, high-quality results, nanosecond welding is a significant advancement in industrial welding, particularly for the energy and battery storage sectors.

Have questions about optimising your battery laser welding process?

Contact our laser technology experts to discover how nanosecond laser welding can enhance your energy and battery storage manufacturing, driving innovation and efficiency forward.