Nakamura-Tome NT-Flex: Powerful, multitasking CNC lathe

Nakamura-Tome NT-Flex: Compact multitasking CNC lathe delivering power, precision, and flexibility for modern manufacturing needs.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

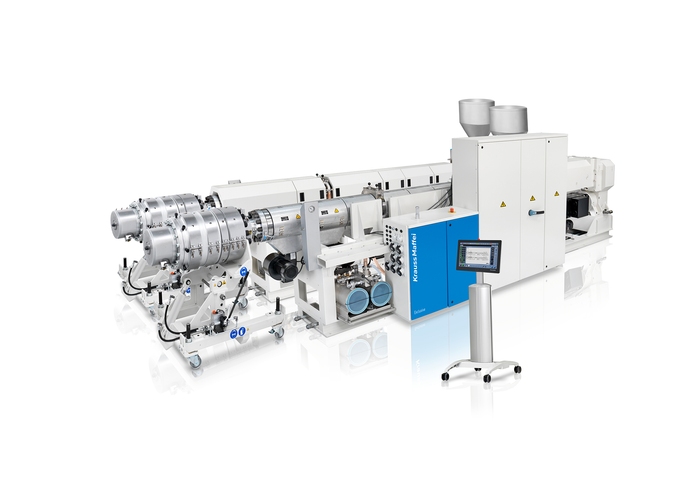

Headland Technology is offering the QuickSwitch from KraussMaffei’s flexible pipe extrusion line system to the Australian market. This technology allows for rapid dimension changes in pipe extrusion, enabling flexible and efficient production of pipes. The QuickSwitch system is well-suited for the Australian market, which requires manufacturing agility due to variability in pipeline product specifications and standards. Additionally, KraussMaffei’s system ensures consistent production of high-quality pipes across multiple dimensions, which is crucial for many Australian manufacturers. Headland recognised the opportunity to introduce this leading technology, as it has already proven successful in the Canadian market. This sets Headland apart from competitors who do not yet offer this advanced solution. The QuickSwitch system provides differentiated, next-generation pipe production that aligns with Headland’s goal to supply innovative piping solutions, not me-too products, to Australian customers.

Seeking the ideal production technology for its new pipe manufacturing plant in Manitoba, Canada, Encoma Ltd set clear goals under plant manager Derek Hofer, efficient production of high-quality HDPE pipes using innovative methods, not me-too products. With the first North American installation of a cutting-edge flexible pipe extrusion line QuickSwitch system from KraussMaffei, the industry newcomer realised its ambitions. Krauss-Maffei’s QuickSwitch extrusion system shortens dimension changes in PO pipe extrusion. The success has already led Encoma to order two additional KraussMaffei extrusion systems.

About Encoma: Encoma Ltd, a family business situated in rural Canada, manufactures high-density polyethylene (HDPE) pipes. Using premier extrusion equipment, they create premium pipes on their spacious 63,000-square-foot factory floor. Encoma pristine manufacturing conditions and top-grade resin let them supply pipe along with the necessary fittings and tools at very reasonable costs. As a local company, Encoma strives to serve our community with exceptional products.

Opening its factory in fall of 2021, Encoma began manufacturing multi-layer HDPE pipes for diverse applications. KraussMaffei installed a complete 3-layer QuickSwitch extrusion line handling the full production process. Derek Hofer, Encoma’s Plant Manager, affirms:

“For us as a newcomer in this branch of industry, it was extremely important to have a competent partner at our side who would be able to set up a turnkey plant on our premises and also provide training and support.”

He adds that there is no reason to regret the purchase decision because KraussMaffei has fully met all expectations. What’s more, Encoma is so satisfied with the plant technology and machine supplier that the company ordered two new lines just three months after the start of production – a second QuickSwitch line and a 5-layer PE-RT line specifically designed for underfloor heating pipes. Derek Hofer explains:

“Quality, reproducibility and production time achieved with the first QuickSwitch line for HDPE pipes were so convincing that we decided to go straight back to KraussMaffei as our machine supplier.”

QuickSwitch stands out as the distinctive package solution developed by KraussMaffei, facilitating the flexible production of pipes with varying dimensions on a single line, eliminating the need for retooling. At the heart of every QuickSwitch line lies the adjustable calibration basket, which seamlessly configures new pipe dimensions automatically and swiftly without interrupting the production process. The waste generated during this “quick switch” phase is minimized to a cone-shaped material piece, contributing not only to heightened efficiency but also promoting sustainability in hose production.

Beyond the effortless alteration of pipe dimensions at the touch of a button, QuickSwitch ensures precise adjustments to pipe wall thickness and centering—critical parameters for the production of top-quality pipes. Once production data is saved, it can be easily accessed and modified at any time, ensuring exact reproducibility. The integrated control system seamlessly adjusts all downstream equipment automatically, eliminating the need for manual readjustment. The intelligent control system allows for comprehensive monitoring, documentation, and correlation of all production parameters, enabling the line to self-manage with minimal personnel effort.

In essence, the KraussMaffei QuickSwitch extrusion line system emerges as the optimal solution, especially for industry entrants like Encoma. Having already implemented the system at their site, Encoma successfully produces pipes with diameters ranging from 25 to 63 mm. The newly ordered line is poised to expand the dimensional range, accommodating sizes up to 6 inches (168/175 mm). Derek Hofer expresses deep confidence in the company’s readiness for future growth, thanks to this finely tuned machine solution that enables diverse pipe production to meet evolving customer demands, even in small quantities.

This innovative system maximises flexibility, efficiency, and responsiveness by enabling fast size changes. Connect with our experts to learn how implementing QuickSwitch could benefit your operations. We would be happy to discuss your production needs and determine if QuickSwitch is the right solution to help you better meet customer demand and stay competitive. Please reach out for more details or to schedule a consultation with our knowledgeable team.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

PO pipe extrusion dimension changes are shortened by Krauss-Maffei’s QuickSwitch extrusion system.

The 36D series’ twin-screw extruders that operate in parallel are made specifically for processing PVC. Their aim is to achieve maximum economic efficiency by means of optimal product quality and high output.

KraussMaffei supply systems that are customized to your specifications for each pipe application, all from one source.