Introducing MyHeadland: Your new customer portal

MyHeadland is here; your 24/7, all-in-one view of everything that matters to you, in one secure place.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

A few years ago, Freighter Group Operations (previously MaxiTRANS) was seriously considering scrapping its business in heavy-duty truck trailer manufacturing. It seemed all but over for the Australian company, which had spent decades building up its production facilities, relying heavily on manual processes and a skilled workforce. Now, high labour costs and long lead times were eating into its profits, and it faced a crucial decision. In a Herculean effort, the management team opted to transform the company’s old manufacturing facility into a Smart Factory. They figured it would take three tough years to turn things around – and now the company is seeing the first signs of success.

About Freighter Group Operations Pty Ltd.: Freighter Group Operations Pty Ltd. formerly known as MaxiTRANS is a leading Australian transport solutions provider for over 75 years, offering road, bulk, and refrigerated transport services with innovative design and comprehensive support. They have strategically located facilities across major transport hubs and offer round-the-clock support across the entire transport lifecycle. They are committed to advancing transport technology and safety, nurturing their team, and contributing to the industry’s growth. They continue to pioneer solutions that make Australian transport safer, more efficient, and increasingly reliable. More about Freighter Group

Freighter Group Operations Pty Ltd. found itself at a crossroads. The company struggled with inefficiency and outdated manufacturing methods, losing market share to more modernised competitors after failed attempts at automation and digitalisation.

Greg L’Estrange was working in the company’s facility in Ballarat when his phone rang. On the other end of the line was a forklift driver from the factory.

“He asked me about one particular part. He wasn’t entirely sure where it was meant to go, but he had already worked out what he was going to do with it,” – recalls L’Estrange, Executive Chairman of Freighter Group. This casual conversation between a worker and a chief executive may seem surprising, especially given Freighter Group Operations’ size and prestige as Australia’s leading manufacturer of semi-trailers.

But L’Estrange and his right-hand man general manager Brad Givvens are big believers in flat hierarchies. Both men favour a straight-talking, down-to-earth approach and are happy to chat with us on the shop floor clad in their work gear. Together, they embody the spirit of the forging shop where the Freighter Group Operations story began – even though L’Estrange only joined the company three years ago. From its humble beginnings, MaxiTRANS has grown into a manufacturing powerhouse employing 700 employees, with a turnover of 400 million Australian dollars last year.

But a few years ago, things looked a whole lot bleaker. They were stuck in an outdated style of manufacturing, and its inefficient methods were causing costs to spiral. The company’s initial attempts to digitise and automate processes were in vain, and Freighter Group soon found itself losing market share to its competitors. When a group of private investors acquired the company three years ago, it felt like everything was on the line. The jewel in Freighter Group crown, its manufacturing operations, were on the brink of being shut down.

The solution proposed by the new owners – among them Greg L’Estrange – seemed like the most rational and logical way forward. The idea was to close down the entire struggling manufacturing business, including the main production site in Ballarat, 100 kilometers northwest of Melbourne. They would then switch to importing trailers from abroad and focus all their efforts on sales.

“The right technology gives us the key to the door, but we’re the ones who decide whether or not to walk through it.” – Greg L’Estrange, executive chairman of Freighter Group.

The money they would raise by selling the manufacturing facilities was certainly tempting – but things ultimately took an unexpected twist. The owners suddenly made a 180-degree shift: instead of selling the factories, they decided to divide up the company and invest heavily in manufacturing.

“We anticipated seeing no return for three years and pumping all our cash flow back into the business,” says L’Estrange, who lobbied the investors to back the new approach.

Over the long term, he figured that this option would produce higher returns than selling the manufacturing facilities.

“Fortunately, we passed up the opportunity to make a quick buck and agreed to go for the second option!” says L’Estrange.

His task then was to bring their traditional factories to the forefront of high-tech manufacturing in just a few years. The goal was to reduce operating costs and double production volume to secure the company’s long-term profitability. But how was such a radical turnaround to be achieved? MaxiTRANS had virtually no experience in modern manufacturing technology, and the few attempts it had made to update its facilities were unsuccessful.

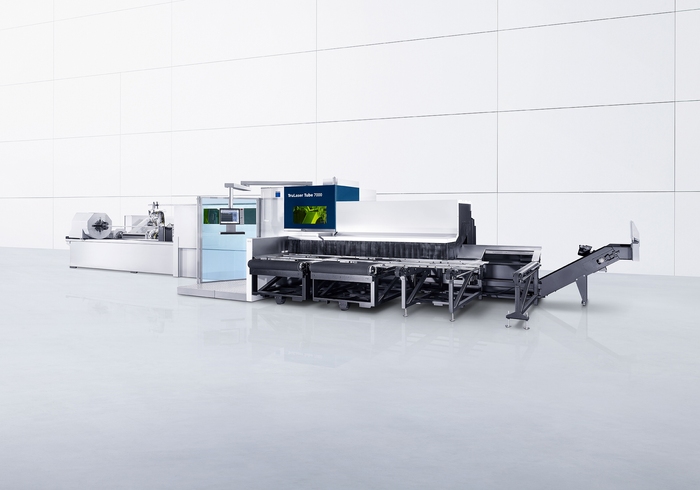

It quickly became apparent that Freighter Group needed to find some experienced partners – and the combination of TRUMPF and local company Headland Technology proved to be a perfect fit. MaxiTRANS put machines and software from the Ditzingen-based family-run company at the heart of its strategy to create a “Factory 4.0”. At its main Ballarat site alone, the company invested 50 million Australian dollars – equivalent to over 30 million euros – in new machines. From TRUMPF, MaxiTRANS acquired a TruLaser 5040, a TruLaser Tube 7000, two TruBend 5000s and a STOPA large-scale storage system. It also opted to incorporate TRUMPF’s Oseon software solution into a new SAP-based IT architecture. The management team is now working flat out to embed the new machines into its production processes, and L’Estrange calculates that their transition to a smart factory will be complete by early 2026.

Freighter Group’s ongoing transition is a testament to the power of investing in the right technology and fostering a culture that supports innovation. The project is on track to complete its smart factory transformation by 2026, ensuring the company’s position as a leading manufacturer of top-quality trailers.

Machinery:

To explore solutions tailored to your business and discuss how TRUMPF technology can help you achieve a smart factory transformation, contact our TRUMPF experts. Our team is ready to assist you in finding the right equipment and software to revolutionise your production process.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Ideal for customers who wish to expand their production but do not yet require maximum productivity.

The TruLaser Tube 7000 Fiber: Technology Designers Love. Cover a wide range of parts and open up new areas of application.

The automated press brake system from TRUMPF ensures a reliable process and a smoothly controlled automation.