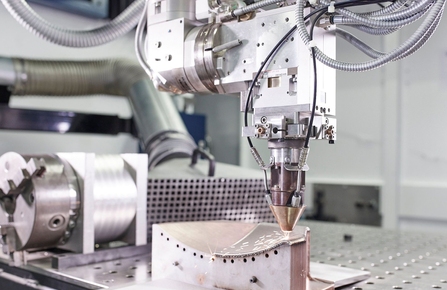

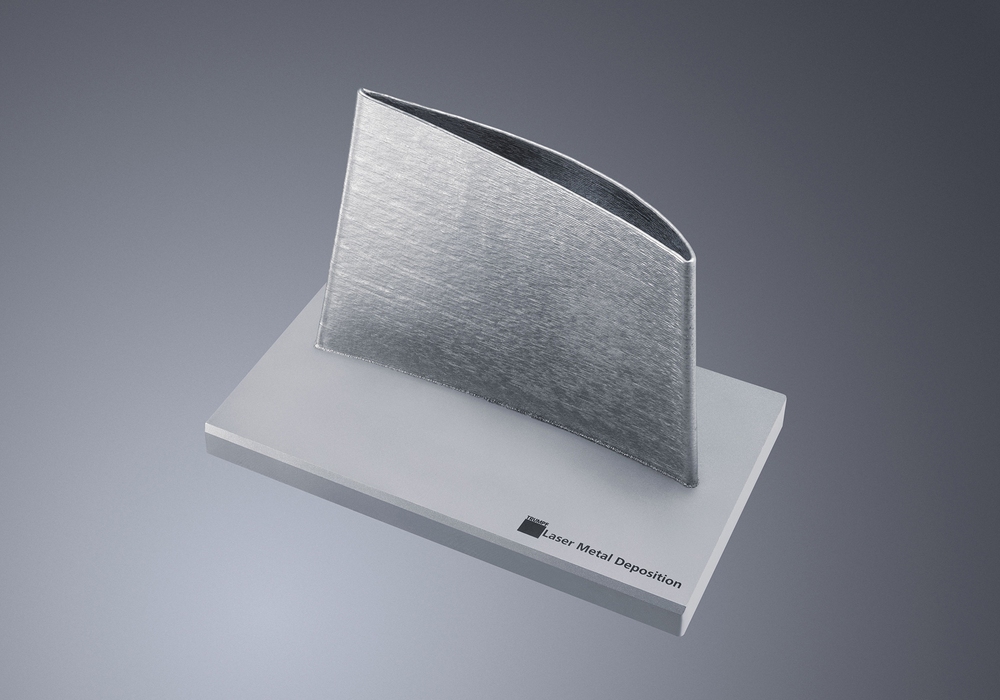

Laser Metal Deposition (LMD) has benefits that extend far beyond simple repairs of worn parts. It’s a versatile additive manufacturing process used for repairing damaged components, creating new parts with complex geometries, modifying designs, and adding functional coatings. Laser Metal Deposition, often referred to as laser cladding, is at the forefront of the shift to advanced manufacturing technologies, offering the ability to extend component lifespans, reduce material waste, and enhance part performance.

This case study explores how Toolcraft AG, a pioneering precision engineering company, worked with TRUMPF to implement a customised LMD solution using the TRUMPF TruLaser Cell 3000 — enabling them to meet demanding customer requirements and transform their production capabilities.

About Toolcraft AG: Founded in Germany, Toolcraft AG is a trailblazer in the field of high-precision manufacturing, specialising in additive manufacturing, high-end mould making, and CNC machining. The company serves a diverse customer base across industries such as aerospace, automotive, medical technology, and consumer goods. Committed to innovation, Toolcraft continuously integrates cutting-edge technologies to maintain its leadership in precision engineering. More about Toolcraft AG

Challenge

Toolcraft was approached by a global consumer goods manufacturer with a challenge: develop a cost-effective method to produce a specialised tooling component featuring a structured functional layer.

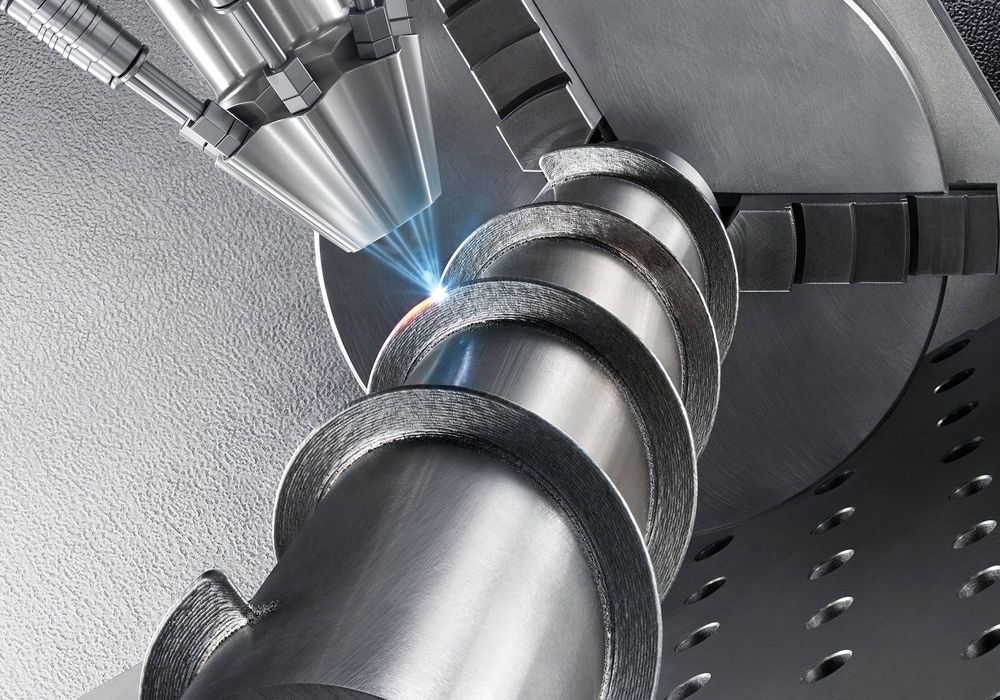

Previously, the entire part was manufactured from high-quality material using a time-consuming milling processes. Toolcraft proposed a hybrid solution — using a more affordable base material for the tool body, while building up the functional structures using Laser Metal Deposition.

This approach required a machine capable of highly precise, rotationally symmetrical processing for large, heavy parts. The solution also needed to accommodate various part geometries while integrating seamlessly into Toolcraft’s existing high-tech manufacturing environment.

Solution

To meet these unique needs, Toolcraft AG turned to TRUMPF and selected the versatile TRUMPF TruLaser Cell 3000, a five-axis laser machine well-suited for LMD, welding, and cutting. TRUMPF, known for its custom engineering capabilities, tailored the machine with several key modifications:

- Rotational and feed units: A 6-metre machine bed was added to accommodate longer parts, along with a heavy-duty rotational axis to enable processing of large and heavy components.

- Synchronised drives: Synchronised rotary axes ensured precise processing of components with varying lengths, allowing for flexibility in part handling.

- Modular option module: A 2D cutting support and flexible fixture interface were integrated, enabling quick reconfiguration for components without rotational symmetry.

These enhancements allowed Toolcraft AG to process both symmetrical and asymmetrical components efficiently, applying high-precision structures using LMD while significantly reducing material use and production costs.

Implementation

The integration of the modified TRUMPF TruLaser Cell 3000 into Toolcraft’s workflow was executed through close collaboration between Toolcraft and TRUMPF engineers. The extended machine bed and synchronised axis control streamlined the setup and handling of large components, while the modular fixture interface allowed Toolcraft to quickly switch between different job types with minimal downtime.

This setup enabled Toolcraft to shift away from traditional subtractive processes toward an additive hybrid model. The result was a more sustainable and economical production method for complex tools — with increased speed, reduced waste, and greater customisation.

Moreover, the successful deployment of this system showcased Toolcraft’s dedication to innovation and the transformative value of working with a technology partner like TRUMPF.

Could you increase part performance and decrease unit costs by implementing LMD for advanced component manufacturing?

Speak with our Advanced Manufacturing experts to discover how our tailored solutions — including the TRUMPF TruLaser Cell 3000 and Laser Metal Deposition technology — can transform your operations. Whether you’re aiming to reduce material waste, shorten lead times, or gain flexibility in part production, our team at Headland Technology is here to help you lead in the next generation of manufacturing.