Imagine this: It’s another busy Monday morning at your facility. The production line is scheduled to run a large order of steel pipes, but there’s a problem—your team is struggling to retrieve the materials from storage.

Two workers are manoeuvring a forklift to pull a 6-meter pipe from a crowded rack. One misstep, and the pipe swings dangerously close to another worker. Even when they get it out safely, they realise it needs to be rotated before machining, adding another time-consuming step.

Meanwhile, your CNC machine sits idle, waiting for material. Every minute of delay costs money. And you know that if one of your key handlers calls in sick tomorrow, this bottleneck will only get worse. Sound familiar?

The true cost of manual long goods handling

You’re not alone if you’ve accepted these challenges as “just part of the job.” But what if there was a way to:

- Retrieve materials in seconds—without forklifts or multiple workers?

- Eliminate manual repositioning before machining?

- Keep production running smoothly, even with staff shortages?

That’s exactly what STOPA’s automated long-span storage systems (like the LG-E, LG-B, and LG-T) are designed to do.

STOPA automated storage systems for long-span goods: Optimise material handling & production efficiency

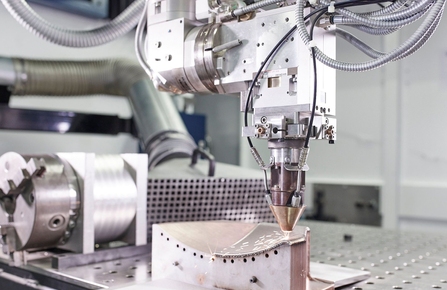

In industries dealing with long-span goods such as pipes, bars, and similar materials, efficient storage and retrieval are crucial for maintaining productivity. STOPA offers automated storage systems designed specifically for long goods, optimising material handling and production processes. Their solutions—including the LG-E, LG-B, and LG-T—feature modular designs, ERP integration, and high storage capacity, ensuring cost savings and operational efficiency.

Why choose STOPA automated storage systems?

STOPA’s long-span storage systems provide:

- Modular & scalable designs: Adapt to growing storage needs

- ERP/WMS integration: Seamless inventory management

- High storage density: Maximises space utilisation

- Automated & semi-automated operation: Reduces manual handling

- Direct machine integration: Streamlines production workflows

STOPA LG-E: Flexible entry-level storage for long bars

The STOPA LG-E is an automated, modular storage system ideal for long bars and similar materials. Key features include:

- Expandable design: Easily scalable as storage needs grow

- Warehouse management software (WMS): Compatible with ERP systems for real-time tracking

- Multiple operation modes: Dead-man, semi-automatic, or fully automatic

- Immediate cost savings: Reduces labour and handling time

This system is perfect for manufacturers looking for a cost-effective, automated solution to optimise long goods storage.

STOPA LG-B: High-capacity storage for long-span goods

For businesses requiring high-density storage, the STOPA LG-B offers:

- Storage for goods up to 9.5 m in length: Ideal for pipes, beams, long materials such as bars, profiles, pipes, extrusions, and rolled metal.

- Capacity for 1,000+ system cassettes: Maximises warehouse space

- Direct machine integration: Connects to processing equipment for seamless workflow

- Advanced WMS options: WMS-Basic 4.0 or WMS-Dynamic 4.0 for optimised storage & retrieval

The LG-B ensures secure, efficient storage while reducing operational costs.

STOPA LG-T: Tower storage for long goods

The STOPA LG-T provides a vertical storage solution, ideal for facilities with limited floor space. Benefits include:

- Compact footprint: Saves space while maintaining high storage capacity

- Automated retrieval: Speeds up material handling

- ERP-compatible software: Ensures accurate inventory management

Key benefits of STOPA automated storage systems

- Reduced labour costs: Automation minimises manual handling

- Improved efficiency: Faster storage and retrieval processes

- Space optimisation: High-density storage maximises warehouse use

- ERP integration: Real-time inventory tracking and management

- Scalability: Modular designs allow for future expansion

But is automation worth the investment?

It’s a fair question. Let’s break it down:

What you’re losing now

- Labour inefficiency: Paying multiple workers to handle materials slowly

- Machine downtime: Production delays while waiting for material retrieval

- Forklift costs: Maintenance, fuel, and operator wages

- Safety risks: Potential injuries leading to workers’ comp claims

What you gain with STOPA

- Faster material flow: No more waiting for manual handling

- Reduced labour dependency: One operator can manage the system

- Space savings: High-density storage frees up floor space

- Fewer accidents: Automated handling removes key risks

Many customers see a full ROI in 2-3 years, just from labour and efficiency savings.

Conclusion

STOPA’s automated storage systems for long-span goods—including the LG-E, LG-B, and LG-T—deliver efficient, scalable, and cost-effective solutions for industries handling pipes, bars, and similar materials. With ERP integration, modular designs, and high storage capacity, these systems enhance material handling, production efficiency, and warehouse optimisation.

Still unsure? Let’s talk through your specific challenges

We get it—this is a big decision. But the real question isn’t “Can we afford automation?”—it’s “Can we afford not to automate?”

Every day you wait:

- Your team keeps working harder, not smarter

- Your machines sit idle, waiting for materials

- Your safety risks remain

Why not explore your options?

Contact our STOPA experts for a no-pressure consultation. We’ll help you determine which STOPA system is the right fit, so you can stop losing time, money, and sleep over material handling.