Introducing MyHeadland: Your new customer portal

MyHeadland is here; your 24/7, all-in-one view of everything that matters to you, in one secure place.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Our range of CNC lathes & Multi-tasking machines are built for unrivalled accuracy. Improve your part quality, increase production and remove risk of errors with combined multi-functional machines.

Nakamura-Tome’s NT-Flex is a multi-tasking CNC lathe designed for high efficiency and flexibility in machining operations.

The first of Nakamura-Tome’s “V series” multitasking machines, with speed as primary design principle.

Nakamura-Tome’s WY-100II CNC Milling Machine provides extremely powerful features like pinch milling, drilling, and turning.

Vertical Turning Center, designed with advanced technology, shows excellent performance in rigidity and precision

Multi-Axis Turning Center, designed to multitask and maximize productivity, shows high rigidity and precision

The L2600Y/LY features a 30° slant bed design which was developed using finite element analysis (FEA) to absorb vibration and minimize thermal growth,

The Nakamura NTRX 300 multi tasking machine tool is specifically for complicated part manufacture.

The JX-200 is an ATC multitasking machine equipped with the world’s shortest tool spindle “NT Smart Cube”.

The Nakamura-Tome JX-250 offers high rigidity ATC type multi-tasking with the world’s shortest tool spindle and Y-axis standard twin turret.

The leading provider in complete turn mill technology, WFL brings together the multi-functional turning and milling combination.

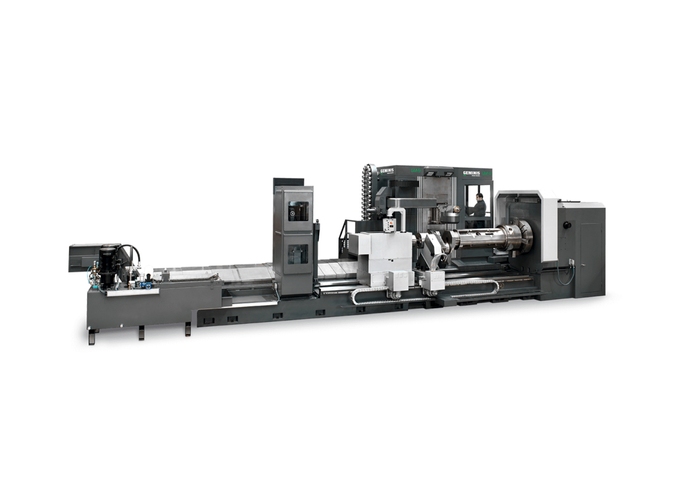

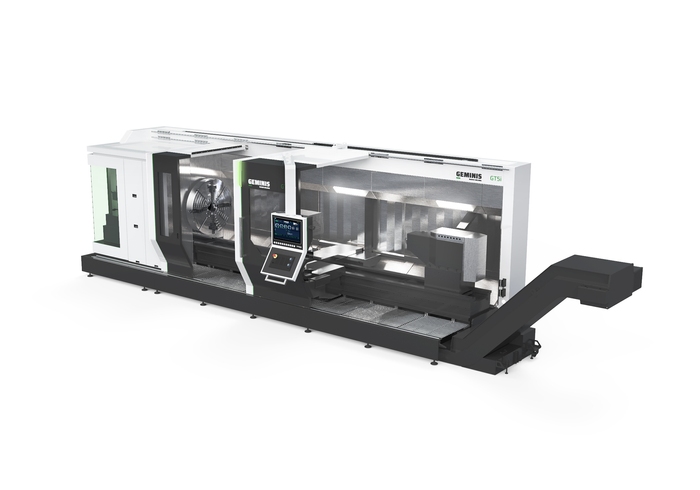

Geminis’ multifunction machines combine lathing, milling, boring and grinding operations. Finish your parts in one integrated session.

The range boasts high rigidity, ergonomics and customisations. The SMART Manufacturing option also enhances your insight into the machine.

The VTL C series’ flexible design combines manufacturing modules to give the customer a solution that is customised to meet their specific requirements.

In order to achieve a very rigid design that offers an ideal balance between strength and weight and significantly increases the stiffness needed during machining, structural analysis was carried out.

Customers have praised the Citizen A20 as a high-capability, low-cost machine solution. We are now introducing the A320VII model, which provides the option to switch between guide bushing and non-guide bushing modes.

Introducing the D25, which includes a B axis and double gang tool posts. Short cycle times and high productivity at low part costs are made possible by the double gang layout.

The next-generation L32, which has a history as one of the best-selling Cincom machines, debuts with 4 models in a modular design.

We can help find the perfect machine for your factory needs. Please fill out the form and one of our CNC specialists will get in touch with you soon.

In addition to supplying you industry-leading manufacturing equipment, we provide machine servicing, software support and smart manufacturing consulting for all our brands.