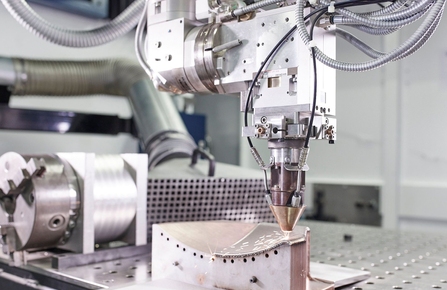

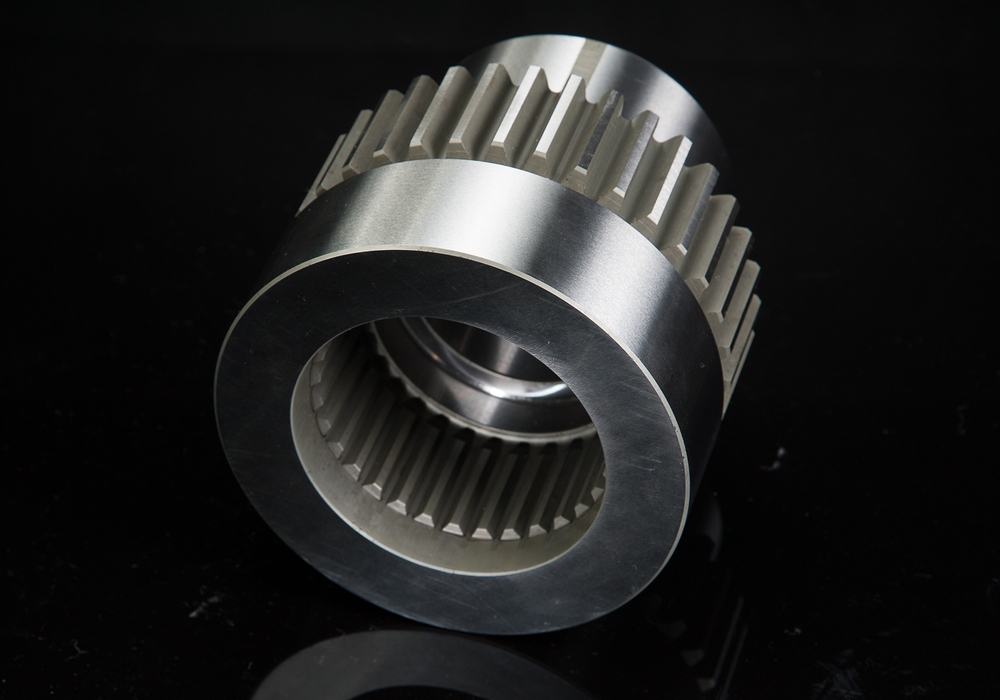

Faced with growing global demand, local precision gear manufacturer Ronson Gears needed to overcome challenges in milling capacity and capability. With the benefit of the advice from Headland’s CNC expert Craig, Ronson Gears chose the horizontal 5-axis Makino a500Z with a 14-pallet system as the ideal solution to move their operations forward and to stay ahead of the competition.

In an interview with Jason Graham, Technical Manager at Ronson Gears, we gained insight into the journey from identifying the problem, to implementing the solution, and realising tangible results.

About Ronson Gears: Precision since 1954 – Founded by Ronald Charles New, Ronson Gears has been delivering high-precision gear solutions to Australian businesses for over 70 years. What began as a local operation in Victoria has grown into a globally trusted manufacturer servicing industries from outer space to undersea mining.

Ronson Gears is renowned for its full-service manufacturing capabilities covering turning, milling, gear cutting, grinding, and advanced measurement. With 46 employees and a 24/6 operation across three shifts, Ronson Gears continues to invest in automation and Industry 4.0 solutions to drive efficiency and global competitiveness. More about Ronson Gears

The challenge

According to Jason Graham, who has been with the company for over three decades, the primary issue was throughput.

“We had a large backlog of work. Our equipment just wasn’t technologically advanced enough for what we were doing. Setups were taking far too long,” he explained.

Ronson Gears was also facing global competitive pressures. Staying ahead meant investing in modern technology that would minimise manual intervention and allow continuous, flexible production. The company needed a solution that could integrate seamlessly into their operations while maximising uptime and capacity.

The solution

After attending EMO 2023 in Germany, Jason explored a variety of advanced machining technologies. Jason says:

“Initially, I was considering a more basic 3+1 axis twin-pallet machine — I hadn’t planned on exploring a multi-pallet system, but during my EMO visit, I came across some and was genuinely impressed. After returning to Australia, I began sourcing quotes and re-evaluated our options. I was already familiar with the Makino brand, and when I investigated the a500Z and reviewed its specifications, it immediately stood out. The machine wasn’t the cheapest on the market, and I’ll admit I haggled quite a bit with Headland’s Sales Representative, Craig, but ultimately, the technical capability and build quality of the Makino sold me. I knew it was the right solution for us.”

Although considering other machines, the technical specifications and top-quality build of the Makino machine impressed.

“I thought Makino was out of reach for us… but after working with Craig from Headland, the numbers made sense. It wasn’t the cheapest option, but we realised it would pay off in the long run.”

The decision to invest in the Makino a500Z with a 14-pallet pool was based on productivity gains, risk minimisation, and the ability to grow their business into new markets with more reliable technology.

Implementation

Headland Technology ensured a smooth delivery and installation process, despite minor shipping delays. Jason noted:

“Overall, it was well-organised and installed on time. Within the second week, we were already seeing 75% spindle uptime”

Once running, the machine quickly integrated into their 24-hour, six-day operational rhythm. The ease of use and automation reduced downtime and enabled quicker responses to production changes. Jason adds:

“We saw immediate benefits. Jobs that used to take 10 hours for setup now run with virtually no lost time. It’s a game-changer in terms of flexibility and planning.”

Results

Since commissioning the Makino a500Z, Ronson Gears has experienced:

- Reduced setup times: Pre-tested programs and fixtures allow for uninterrupted production.

- Greater flexibility: The pallet pool system enables easy prioritisation of urgent jobs.

- Maximised capacity: Even with full-time operation, the machine still has capacity for more work through staffing adjustments.

And increased operator enthusiasm:

“There’s been a lot of excitement about the machine; it’s a joy to use,” Jason added.

Service and support

Ronson Gears appreciates the long-term relationship they’ve developed with Headland Technology. Jason clarifies:

“Service and support are vital. With Headland, I can always get someone on the phone—unlike other suppliers where we’ve struggled. That quick response makes all the difference.”

The strong after-sales service reinforced their decision to choose both the Makino machine and Headland as a trusted partner.

Lessons learned

For other manufacturers considering a similar investment, Jason offers clear advice:

“Stretch your budget if you can. Investing in quality pays back in performance and reliability. My mentor always said, “Buy the best you can afford, and it will reward you over time.”

Looking ahead

Ronson Gears continues to see potential to grow despite running a high-output schedule.

Jason continues to say:

“We have the space and now the capability. The next challenge is hiring more of the right people, which many in manufacturing are struggling with right now.”

Final thoughts

Would you recommend the Makino a500Z and Headland Technology to others?

Jason reply’s:

“Most definitely. It’s a great machine and the service and installation from Headland were first-class. Excellent partnership.”

As Ronson Gears continues to lead the way in precision gear manufacturing, its investment in cutting-edge technology like the Makino a500Z, backed by Headland’s expertise, is a stark reminder of how Australian manufacturers can stay competitive on the global stage.

Ready to future-proof your production and overcome throughput challenges like Ronson Gears?

Contact us and our CNC experts to discover how we can help you find the right machine solution for your manufacturing needs.