British-based Hope Technology, a world-renowned manufacturer of high-performance bicycle aftermarket components, has recently bolstered its machining capabilities by installing its sixteenth Citizen CNC lathes. This marks two decades of consistent investment in Citizen Machinery by the company. The addition of the latest Cincom sliding-head lathes reflects Hope Technology’s commitment to in-house precision manufacturing, enabling them to meet increasing global demand and stringent quality standards. Headquartered in Barnoldswick, UK, the business is a trusted supplier of components across more than 40 international markets.

About Hope Technology: Hope Technology employs around 150 people and exports half its rapidly expanding product portfolio to more than 40 countries. The highly successful British business, which was founded in 1989 by ex-Rolls-Royce aero engineers Ian Weatherill, who is now CEO, and the late Simon Sharp was based on a quest to make mountain biking safer by developing and producing a disc brake as an alternative to less effective cantilever brakes. More about Hope Technology

Challenge

As a rapidly growing manufacturer, Hope Technology was facing significant pressure to maintain high production throughput while preserving stringent precision and quality requirements. Established in 1989 by former Rolls-Royce aerospace engineers, the company has grown steadily by offering market-leading disc brakes and a vast range of other cycling components, all designed and produced in-house.

With demand surging globally and product portfolios expanding, the company’s turning section was nearing full capacity. Their CNC setup, comprising over 70 machine tools, was increasingly strained as customer lead times tightened. Additionally, the production team was tasked with reducing material waste and enhancing lights-out manufacturing to improve cost-efficiency.

Hope Technology required machinery that could handle high-volume bar work with uninterrupted reliability and flexibility to meet the surge in orders and ensure precision across their aluminium, stainless steel, brass, and carbon fibre product lines.

Solution

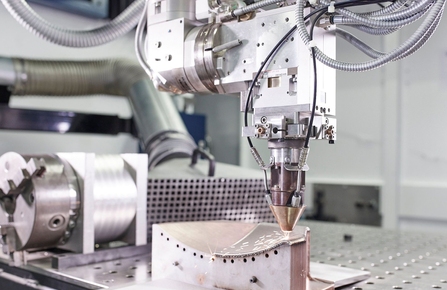

Hope Technology turned once again to Citizen Machinery UK, their long-term CNC technology partner, for a new sliding-head solution. In September 2024, they installed a Cincom A20-VIILFV sliding-head turning and milling centre with a 20 mm bar capacity. Following this, in May 2025, they added a Cincom L12-VIILFV (12 mm capacity). These machines became the eighth and ninth Citizen sliding-head models installed at the Barnoldswick site. Including the seven Citizen Miyano fixed-head lathes purchased between 2013 and 2020, the manufacturer now runs 16 Citizen machines.

Citizen’s Cincom and Miyano platforms were selected not only for their productivity and speed but also for advanced features like LFV (low frequency vibration) chip breaking and guide bush removal capability. The addition of LFV was particularly significant, ensuring clean chip control, reducing downtime, and supporting extended lights-out machining.

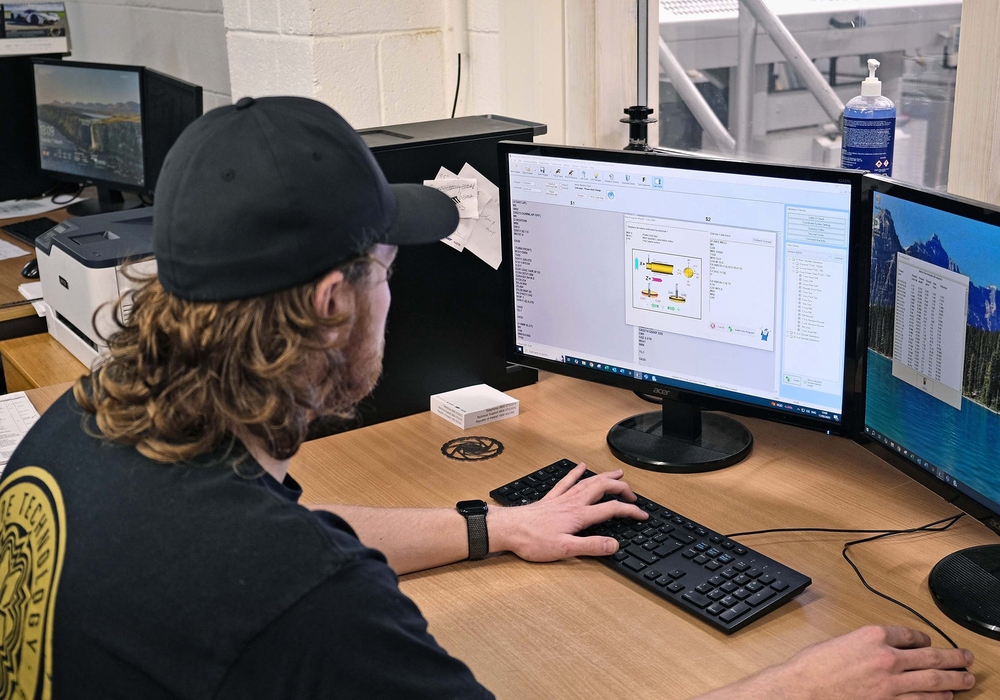

Furthermore, the use of Citizen’s Alkart Wizard software simplified programming, reducing development time and human error while supporting efficient setup across new production runs.

Implementation

The integration of the new Citizen Cincom A20 and L12 models was seamless, supported by Citizen Machinery UK’s expert commissioning and training. The machines were added to the small parts turning section, supervised by Andy Savage, under the leadership of Works and Production Manager Lindley Pate—one of the original members of the Hope Technology team since its founding.

A key focus was optimising the machines for continuous, unattended operation. Retrofitting of swarf conveyors to the newest A20s enabled long-duration machining without swarf buildup. Combined with the programmable LFV technology, this eliminated the risk of chip entanglement, which can lead to part damage, tool wear, or unplanned stoppages.

In parallel, Mr. Savage is preparing to implement guide bush removal on the Cincom machines for shorter part runs. This will allow the use of less expensive extruded bar stock and reduce remnant waste by two to three times—delivering immediate material cost savings.

On the fixed-head side, seven Miyano lathes—six with 42 mm and one with 51 mm capacity—are now the workhorses for larger part production. Components like 7075 aluminium rear cassette lockrings have shifted to these machines, benefiting from shorter cycle times and higher efficiency.

Programming across both Cincom and Miyano machines has been further optimised using Citizen’s Alkart Wizard, which provides a user-friendly interface, visual process guides, and reusable CNC code modules.

Outcome

Hope Technology now runs an advanced, optimised production floor that supports both high-mix, high-volume manufacturing and lights-out machining. Tolerances such as ±0.01 mm on bearing diameters are consistently achieved. The ongoing investment in Citizen Machinery ensures Hope Technology maintains its competitive edge globally while continuing to uphold the quality and performance that define its brand.

Mr. Lindley Pate, Production Manager at Hope Technology, summarised:

“Our continued investment in Citizen machines comes down to their reliability, service support, and production capability. With demand increasing globally, we must keep the product moving swiftly through our factory and out to market. Citizen helps us achieve that every day.”

Are you looking to improve bar-fed component output, reduce waste, or introduce reliable lights-out machining into your operation?

Our CNC and Citizen experts are here to help. We partner with manufacturers across Australia and New Zealand to implement world-class turning and milling solutions—whether you’re scaling up capacity, reconfiguring your machining floor, or exploring automation and chip control technologies like LFV.