Performax International, a leader in the importation and conversion of Ford F-Series Super Duties in (GMC Seira, Dodge Challenger and Charger, Chevrolet Corvette) Australia, has a long-standing reputation for excellence and innovation in the automotive conversion industry. In 2021, seeking to enhance its operational efficiency further, Performax strategically brought all metal fabrication manufacturing in-house. Headland Technology, renowned for providing cutting-edge machinery and technology solutions, offered the JFY EFC II laser cutter, which proved to be the ideal solution for Performax’s needs.

About Performax International: Originally founded in 1989 as Corvette Queensland the company soon transitioned to American pick-ups due to market demand and has become the leading expert in right-hand-drive conversion technology in the Asia Pacific region. For over thirty years, they have been leading the way in providing top-notch, high-performance American vehicles to right-hand-drive markets.

Their journey began with a vision to bridge the gap between the power and allure of American vehicles and the practical needs of right-hand-drive countries. Through relentless innovation and a commitment to excellence, they have transformed this vision into reality, becoming a dominant force in our industry. Today, Performax manufactures 80% of its production parts in-house. For more information about Performax International, visit their website.

Challenge

To maintain its market leadership and enhance its operational efficiency, Performax decided to bring all metal fabrication manufacturing in-house. This strategic move aimed to reduce costs, improve quality control, and shorten lead times. Initially, they purchased a CNC plasma cutter. However, the significant labour required to clean dross and slag from plasma-cut parts soon revealed the machine’s inadequacy for the volume needed. This limitation necessitated a more efficient and reliable solution.

Solution

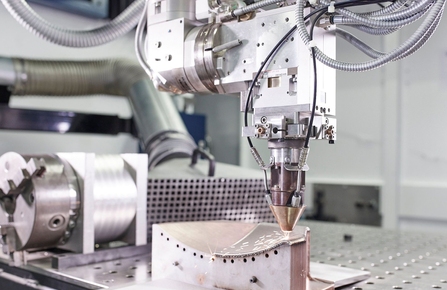

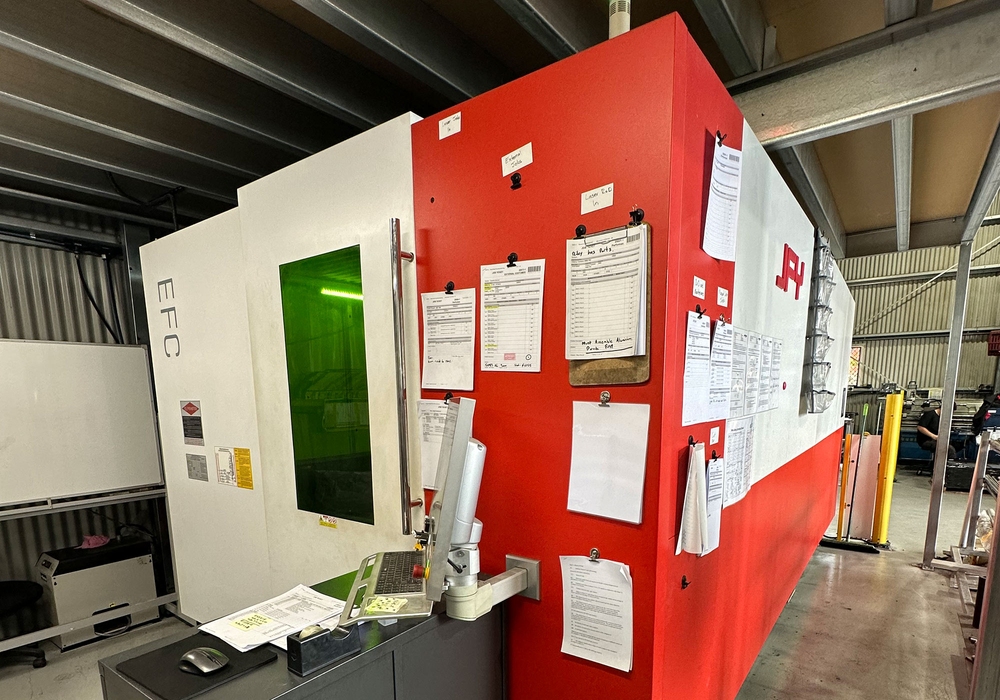

Our metal fabrication experts identified the JFY EFC II laser cutter as the optimal solution to their problem. Featuring a TRUMPF TruFiber laser with up to 6 kW of cutting power, this system delivers exceptional precision and efficiency while remaining a cost-effective and dependable option. Our reputation for excellent customer service and technical support also played a crucial role in Performax’s decision-making process. The laser cutter promised not only to reduce the labour associated with cleaning parts but also to significantly enhance throughput, thereby aligning perfectly with Performax’s operational goals.

Implementation

The integration of the JFY EFC II laser cutter into Performax’s existing operations was seamless. Given their existing setup for sheet metal component manufacturing with a CNC plasma cutter, minimal modifications were required. The laser cutter was quickly incorporated into the manufacturing process enabling a smooth transition without disrupting ongoing processes. Performax’s engineering team, led by Dylan Holt, the Production/Engineering Manager, supervised the implementation, ensuring that the new technology was fully operational in a short period.

Benefits and impact

The adoption of the JFY EFC II laser cutter has yielded substantial benefits for Performax.

Key improvements include:

- Reduced labour costs: The laser cutter has slashed labour requirements for sheet metal cutting by approximately $60,000 annually.

- Increased throughput: Performax has experienced a fourfold increase in maximum throughput, significantly enhancing production capacity.

- Shortened lead times: The average completion time for sheet metal parts has been halved from four weeks to two weeks, enabling faster delivery of products to customers.

- Enhanced agility: The ability to manufacture all sheet metal parts in-house has allowed Performax to iterate designs rapidly, supporting a more agile research and development process. This capability was instrumental in Performax being the first to market with the current model Ford F-Series SuperDuty.

Competitive advantage and innovation

With the acquisition of the JFY EFC II laser cutter, Performax International has maintained its position at the forefront. This advanced equipment has significantly enhanced production capabilities, leading to increased efficiency and a competitive edge. Performax has cemented its position as a leader in automotive conversions by swiftly adapting to market demands and accelerating the manufacture of high-quality products.

Technical support

Headland Technology’s commitment to providing ongoing technical support has been a critical factor in the success of the technology adoption. For a small business like Performax, minimising downtime is essential, and Headland’s knowledgeable service technicians have ensured that the laser cutter operates smoothly, thereby safeguarding the investment.

Future outlook

Looking ahead, Performax plans to further enhance its manufacturing capabilities by investing an additional CNC press brake to address bottlenecks in its pressing capabilities. This planned expansion underscores Performax’s commitment to continuous improvement and operational excellence.

Lessons learned

Performax’s experience with the JFY EFC II laser cutter has been overwhelmingly positive, with no significant issues or regrets. Their advice to other organisations considering similar technology is straightforward: trust in reliable solutions and prioritise excellent technical support.

Is outdated equipment holding your automotive business back?

Learn how a single-machine upgrade boosted efficiency for one automotive industry leader. Reach out to one of our knowledgeable metal fabrication experts to find out more.