Australia’s $500 million Battery Breakthrough Initiative (BBI), part of the Future Made in Australia policy, is designed to build sovereign capability across the battery value chain: active materials, cell manufacturing and pack assembly. Developed under the National Battery Strategy in consultation with DISR and industry, the program accelerates local investment through ARENA.

With funding flowing, the challenge is clear: how can manufacturers stand up scalable, modern production lines fast, and with a trusted partner?

Headland’s role

Headland represents two of Germany’s most respected engineering houses: KraussMaffei (plastics processing) and TRUMPF (industrial lasers). Beyond equipment, Headland provides specification support, integration, lifecycle service, and smart manufacturing expertise, delivering full enablement across the battery production chain.

Injection moulding: Build safe, scalable pack components

Applications: spacers, cell carriers, high-voltage covers, BMS housings

- Benefits: safety, thermal management, manufacturability

- Technology: KraussMaffei all-electric and hydraulic platforms with automation and multi-material option

- Outcome: faster PPAP, stable quality, seamless pilot-to-volume scale-up

Headland delivers turnkey cells: machines, robots, tooling, and inspection, plus lifecycle service to reduce ramp risk and accelerate time to revenue.

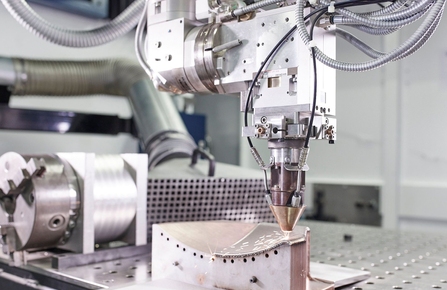

Laser welding: Achieve clean, conductive joints at scale

- Applications: busbars, tabs, cooling plates

- Benefits: high-integrity copper and aluminium welds, speed, traceability

- Technology: TRUMPF TruDisk (green wavelength), TruLaser Station, TruLaser Cell

- Outcome: low-spatter welds, in-process monitoring, digital QA

Headland supports trials, fixturing, automation integration, and long-term service, maximising OEE from day one.

Why it matters for BBI projects

BBI is not about prototypes. It is about building globally competitive domestic manufacturing. Headland lowers execution risk across two bottlenecks:

- Moulded pack components

- Welded electrical and thermal assemblies

The result: Faster factory commissioning, higher first-time-right rates, and Australian teams trained to sustain performance.

Check if your are eligible: Business Grants

For companies thinking about establish local battery manufacturing capabilities and taking advantage of the BBI grants, Headland provides a straight path from approval to qualified production lines, right here in Australia. Talk to us about scoping your project.