In today’s competitive manufacturing landscape, efficiency and precision are non-negotiable. One of the most effective ways to cut production time and costs is by minimising setups and changeovers. While 3-axis milling machines have long been the industry standard, upgrading to 5-axis machining can be a transformative investment.

5-axis CNC machines offer unparalleled flexibility, precision, and efficiency—enabling manufacturers to produce complex parts faster, with fewer setups, and at a lower overall cost. Below, we explore the key advantages of 5-axis machining and how it revolutionises modern manufacturing.

1. Complex geometries: Unlocking design freedom

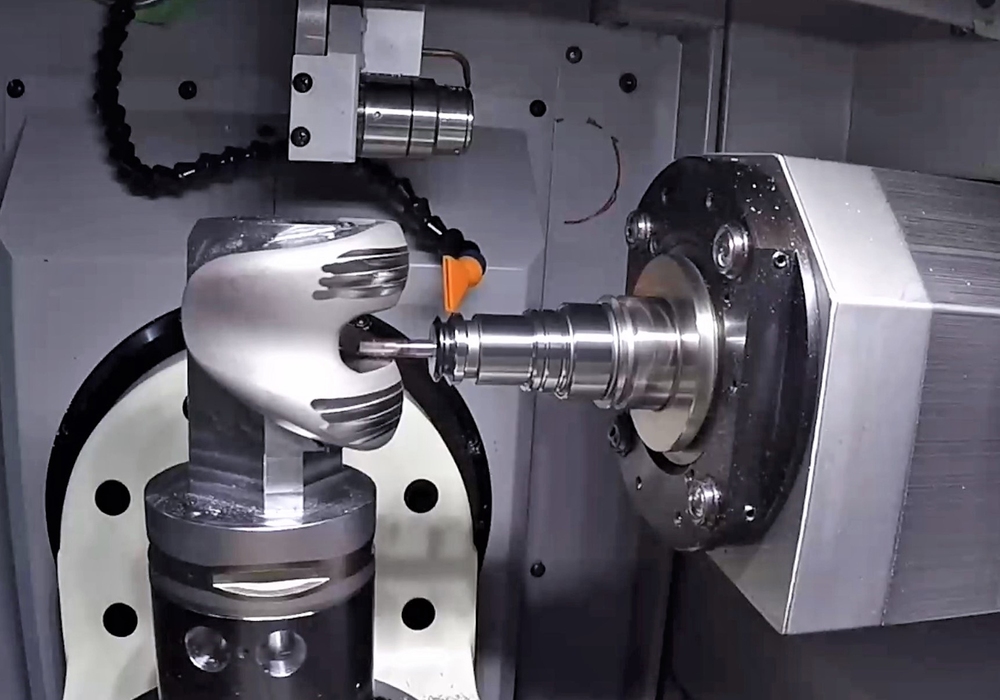

Traditional 3-axis machines are limited to linear movements along the X, Y, and Z axes, making intricate contours and undercuts challenging. In contrast, 5-axis machining allows simultaneous movement along five axes (X, Y, Z, plus two rotational axes), enabling:

- Multi-angle machining without repositioning

- Curved and organic shapes (e.g., aerospace blades, medical implants)

- Undercuts and deep cavities in a single setup

This eliminates the need for multiple fixtures and manual adjustments, reducing errors and accelerating production.

2. Reduced setup times: One operation, one setup

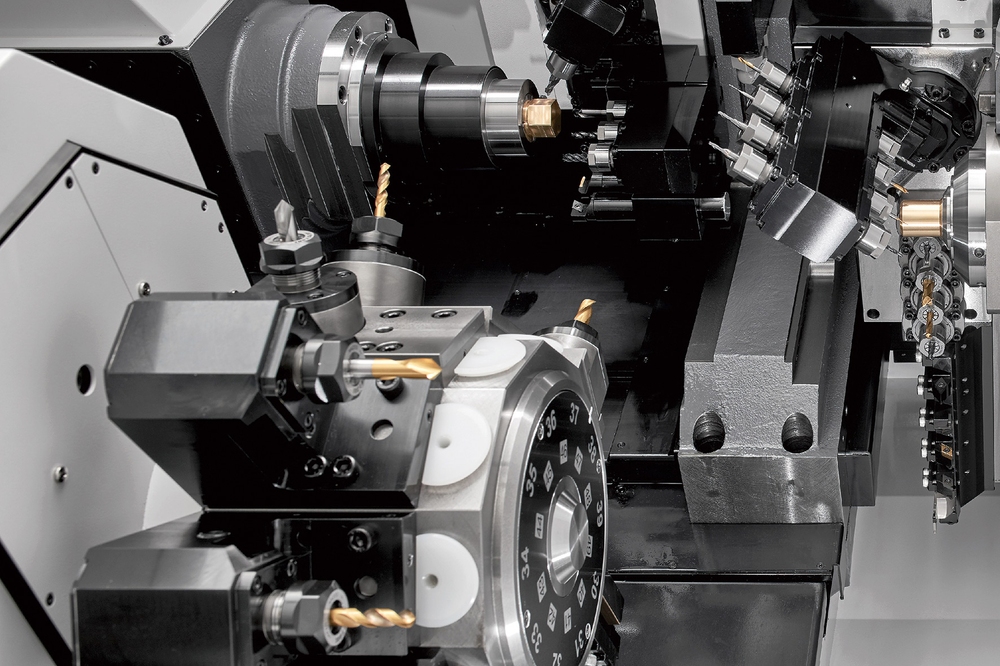

Every time a part is repositioned in a 3-axis machine, accuracy risks increase, and valuable time is lost. 5-axis machining dramatically reduces setup time by:

- Machining 5 sides of a part in a single clamping

- Eliminating secondary operations (e.g., flipping, realigning)

- Reducing human intervention (lower labour costs, fewer errors)

For high-mix, low-volume production (e.g., aerospace, medical), this efficiency is invaluable.

3. Superior surface finish: Fewer secondary operations

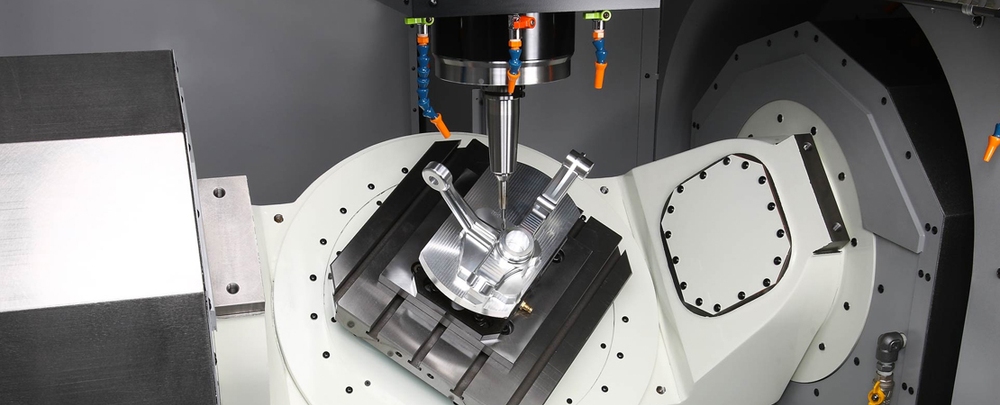

Since 5-axis machines maintain the optimal cutting angle throughout the process, they produce:

- Smoother finishes (reducing or eliminating hand polishing)

- Consistent tool engagement (avoiding tool marks)

- Higher-quality edges (critical for sealing surfaces, aerodynamic components)

This minimises post-processing, saving both time and material costs.

4. Enhanced accuracy & precision: Tighter tolerances

Complex parts often require multiple setups on 3-axis machines, introducing cumulative errors. 5-axis machining improves accuracy by:

- Reducing repositioning errors (single setup = fewer misalignments)

- Maintaining continuous tool contact (better dimensional stability)

- Supporting advanced probing & in-process measurements

Industries like aerospace, defence, and medical rely on these capabilities for mission-critical components.

5. Faster material removal: Optimised tool paths

5-axis machines leverage dynamic toolpath strategies, such as:

- Trochoidal milling (reduced tool load, longer tool life)

- High-efficiency roughing (faster stock removal)

- Continuous 5-axis motion (no retract/reposition delays)

This results in shorter cycle times and higher throughput.

6. Extended tool life: Reduced wear & tear

By maintaining the ideal cutting angle, 5-axis machining:

- Reduces tool deflection (preventing premature wear)

- Distributes wear evenly (prolonging tool lifespan)

- Minimises vibration & chatter (better surface finish)

Fewer tool changes result in lower consumable costs and reduced downtime.

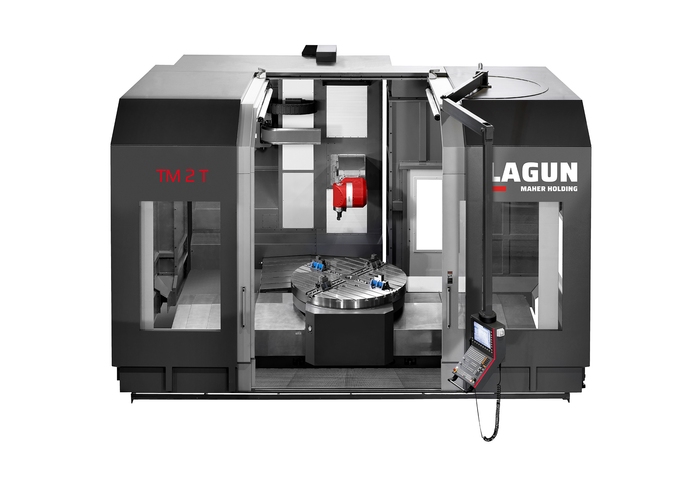

7. Versatility: One machine for multiple applications

5-axis CNC machines excel across industries, including:

- Aerospace (turbine blades, structural components)

- Automotive (prototyping, engine parts)

- Medical (implants, surgical instruments)

- Mould & die (complex cavities, cores)

- Energy (turbine components, oil & gas parts)

8. Long-term cost savings: Efficiency = profitability

While 5-axis machines have a higher upfront cost, they deliver long-term savings through:

- Fewer setups = less labour & machine time

- Reduced scrap = higher first-pass yield

- Lower secondary ops = faster turnaround

- Extended tool life = reduced consumable costs

For manufacturers looking to boost competitiveness, the ROI is compelling.

Conclusion: Is 5-axis machining right for your business?

If your production involves complex geometries, tight tolerances, or frequent setups, upgrading to 5-axis machining can be a game-changing investment. The technology not only cuts setup time and costs but also enhances part quality and design flexibility.

For manufacturers aiming to stay ahead in aerospace, medical, automotive, or precision engineering, 5-axis CNC machining isn’t just an upgrade—it’s a strategic necessity.

The future is 5-axis. Your competitors are already there—are you falling behind?

Our CNC experts deliver precision that wins contracts and efficiency that crushes costs. Your operation demands the edge. Contact our CNC experts and let our proven 5-axis solutions catapult your business ahead.