AMW 2023 is an exciting event where we get to show off the latest and greatest technologies from our partners. This year Headland Technology will be showcasing the Timesavers 10 & 22 series. On our stand you can see these high quality deburring machines turning laser and water jet cut samples into perfectly finished products.

Highly affordable manual deburring with the Timesavers 10 series

The 10 series is a versatile and affordable starter model, suitable for manual deburring, edge rounding and finishing.

If you require a mirror finish on your parts the 10 series is capable of producing this as well.

The 180 degree range rotating shaft on the 10 series also means its quick and easy to switch between different consumables. As as an added bonus Timesavers provides you original spare parts and tooling, so you can keep downtimes low and ensure your machines continue to perform with the best results.

The 10 series is high speed and multi-functional

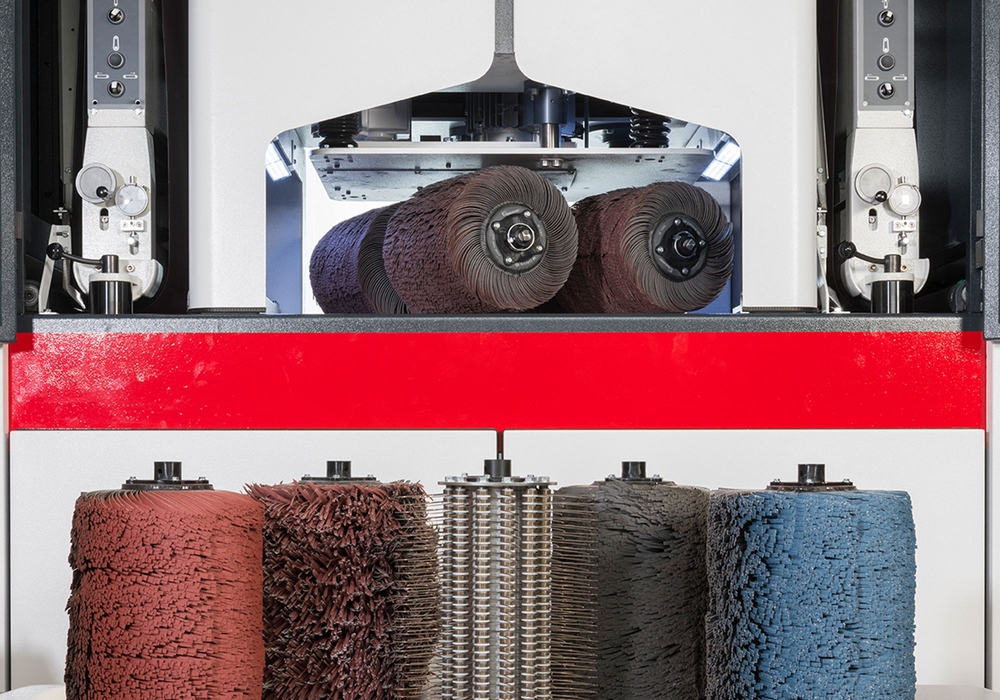

Renowned for its high speed (3-4 times faster than manual edge working), the machine comes equipped with 2 head which can be fitted with a variety of brushes for deburring, edge rounding, finish, laser oxide removal and heavy slag removal.

Automate your dry finishing and deburring of parts with the Timesavers 22 series

The rugged and solid 22 series is ideally suited for the dry finishing and deburring of your metal parts. Unlike the 10 series, this is a fully automated machine. Simply fix your attachment, place your part on the conveyor, choose your setting and the machine takes care of the rest.

The combination of abrasive belt and brush makes the 22 series especially suited for deburring, perfect finishing or heavy slag removal all in one pass.

The relatively small footprint and high production capacity of the 22 make it a perfect addition to your shop floor.

The 22 series works equally well on laser, plasma and flame cut parts

The machine was designed with the deburring, edge breaking and finishing of laser-cut parts in mind, all with low cost to the user. Create round edges and perfect finishes with its multi-disc head with six rotating deburring discs.

The machine is no one-hit wonder and can also perform heavy slag removal if you have plasma and flame-cut parts. The Hammerhead option has a wide belt grinding head for edge breaking and further deburring.

See high quality part finishing in person on our stand

Come visit stand MT440 during AMW where you see the excellent part finishing quality of the 10 and 22 series up close at . The 10 series will be running all day on a series of laser-cut test parts. See a part go from its post laser cutting to a perfectly finished product to get a full picture of the 10 series capabilities. Pascal, our Timesavers representative will be on standby walking you through its functionality in detail and answering any questions you may have.

Experience the 22 series in a production environment

The Timesavers 22 series will also be up and running and part of a mini production line on our stand. As part of our demonstration, we will be taking a raw piece of metal, cutting it with one of our OMAX water jet machine, passing it through the 22 series for finishing and finally marking it with one of our TRUMPF TruMark laser marking machines. You will get a chance to see how exactly the 22 series would fit into a shop floor environment.